Our Frequently Used Products

Discover Our Full RangeHelpful Tools

Hunting for the right blockwork solution for your next project? Start your search by taking a look at our full product range, get detailed information for specification among our Resources or drill straight down to the perfect choice with our bespoke Block Selector tool.

View All Products View All Resources Product SelectorOther buildings

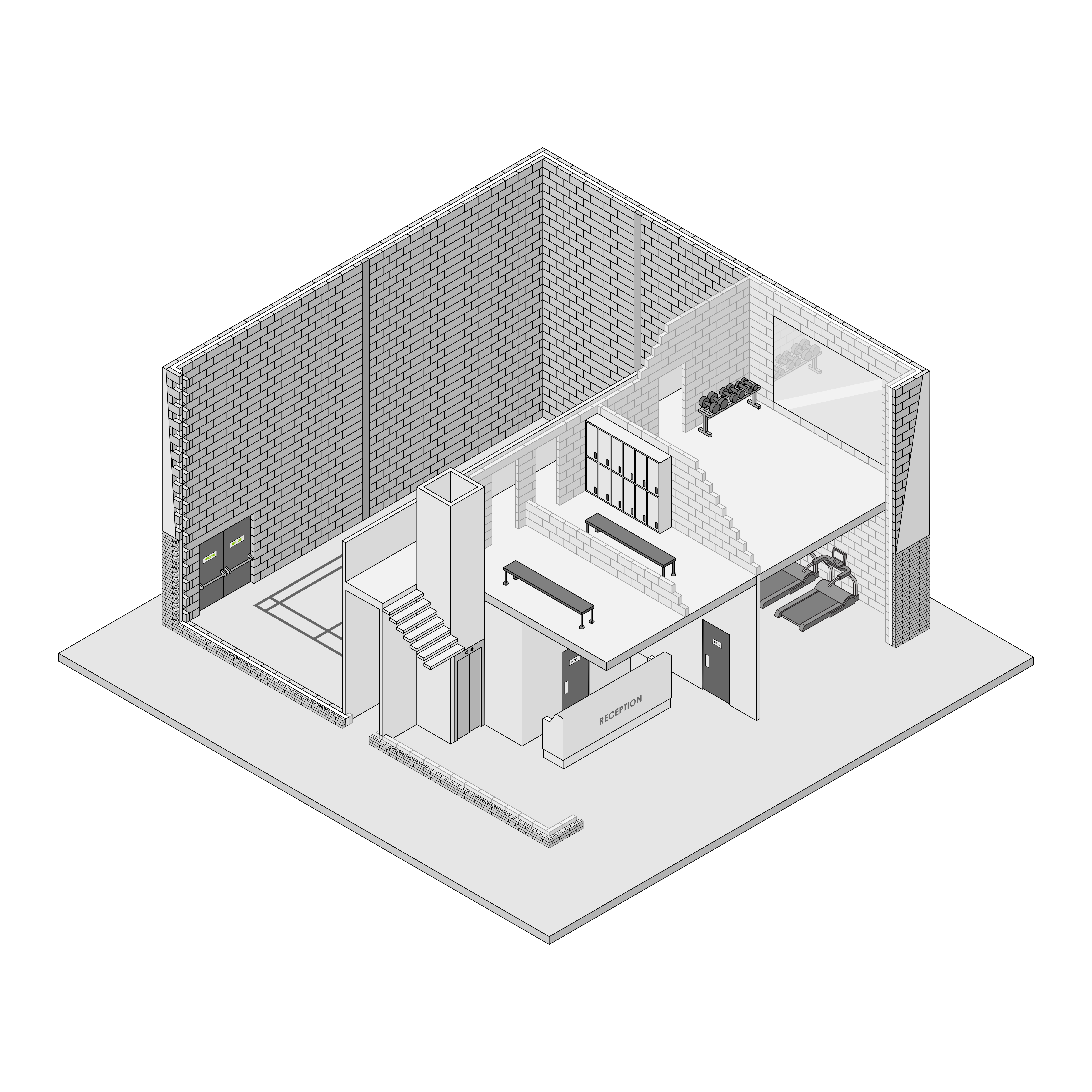

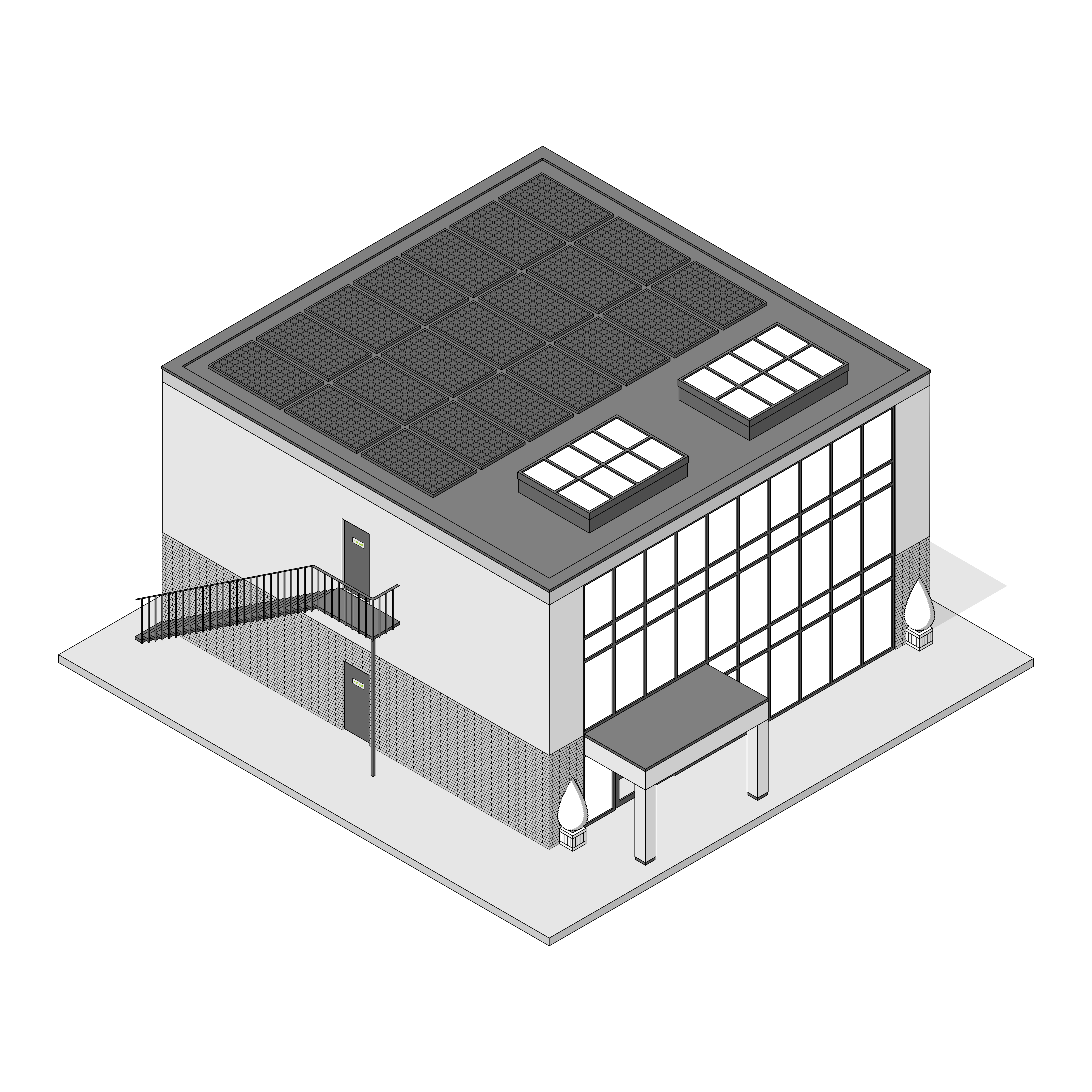

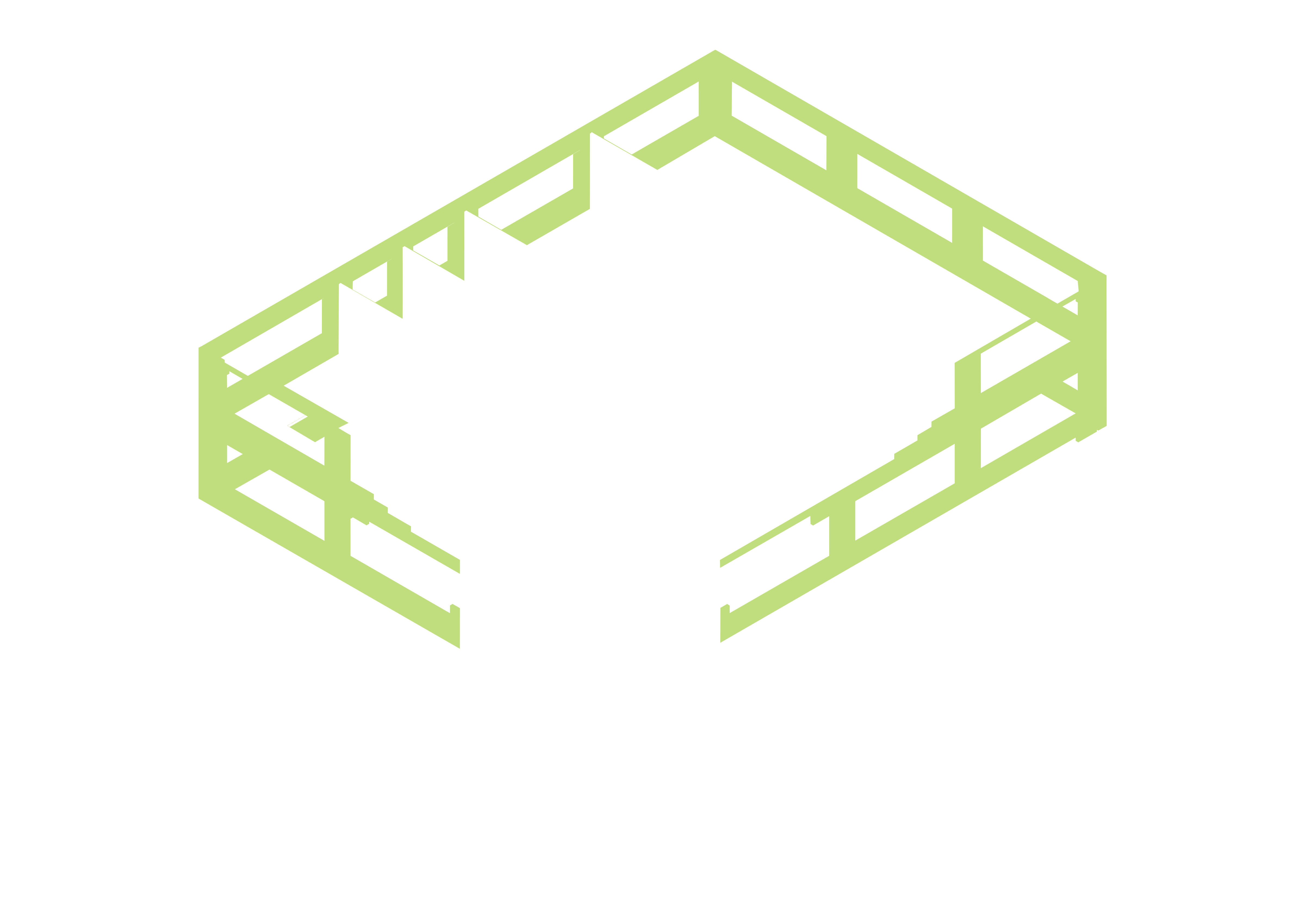

Block Application Locator

Bring your project to life with this interactive tool. Select your building type and use, and get instant recommendations on the blocks to use above and below ground – turning your vision into reality.

Other usesDomestic Housing

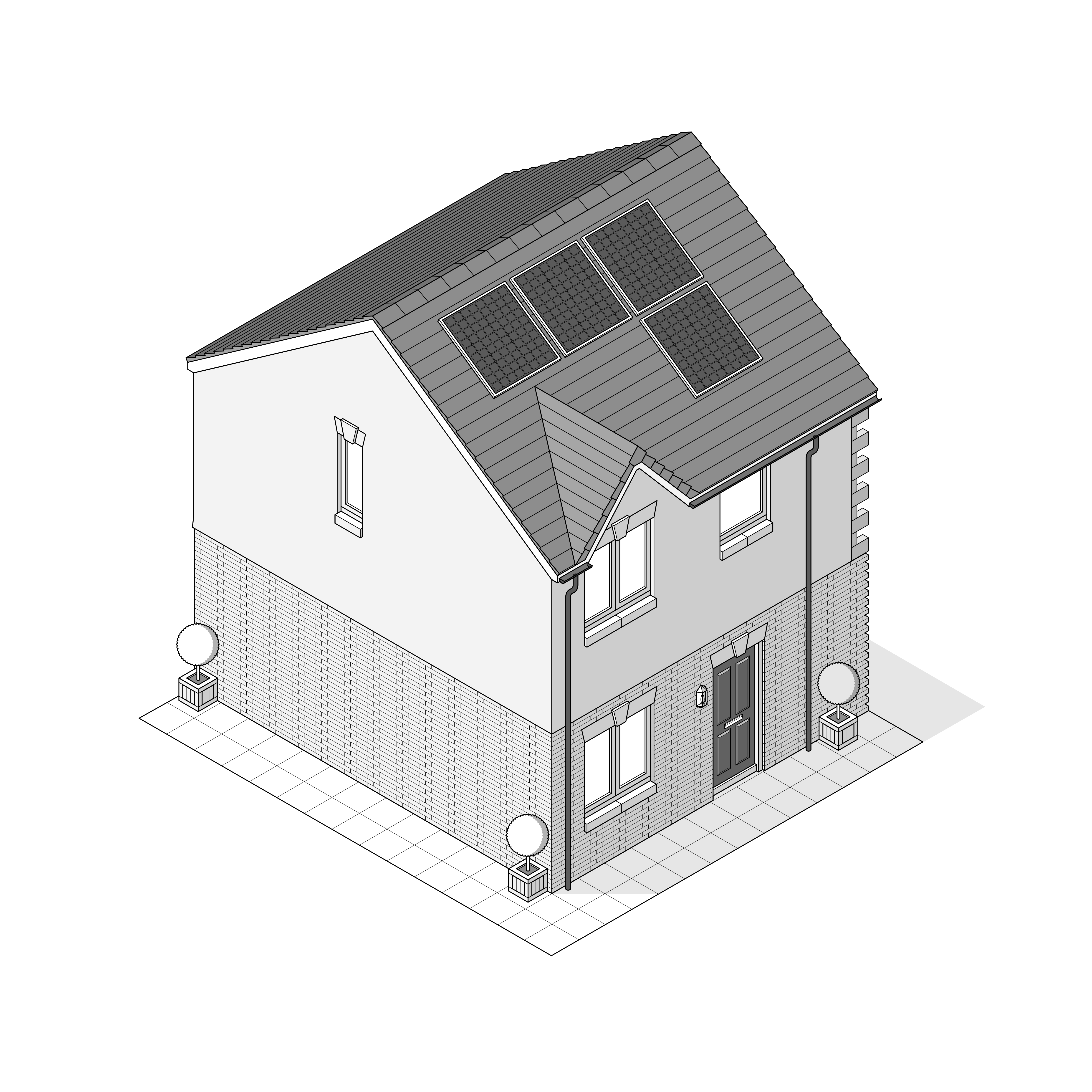

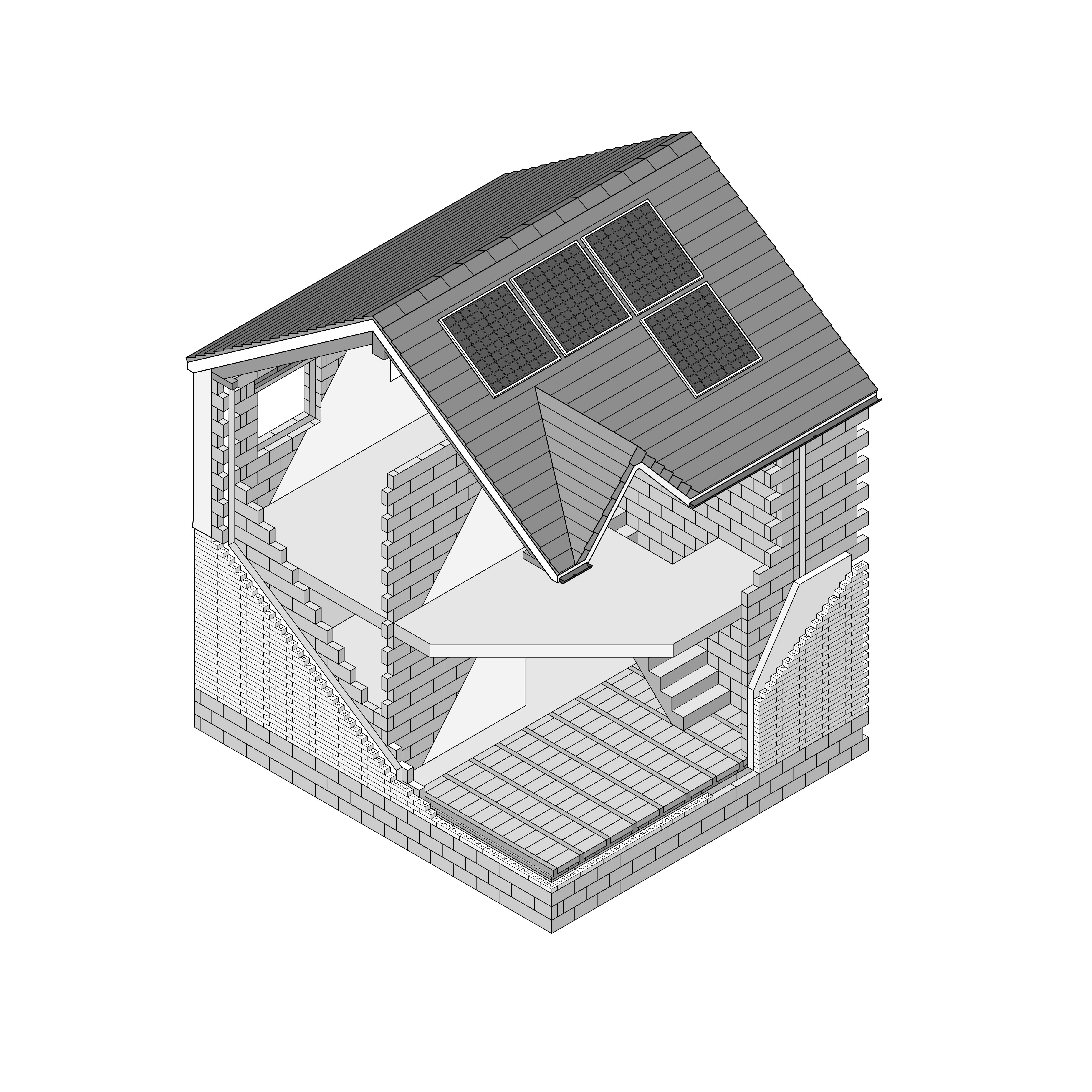

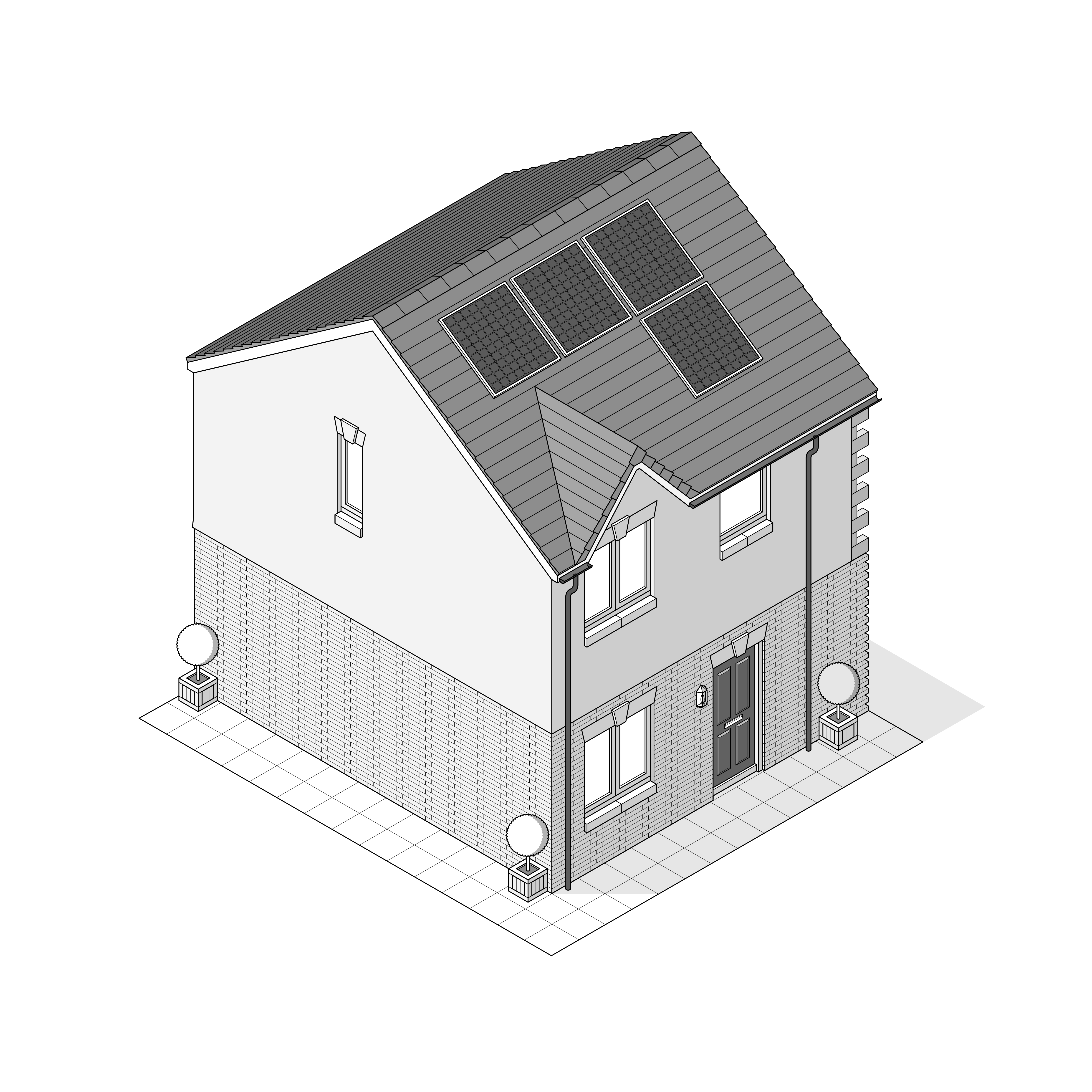

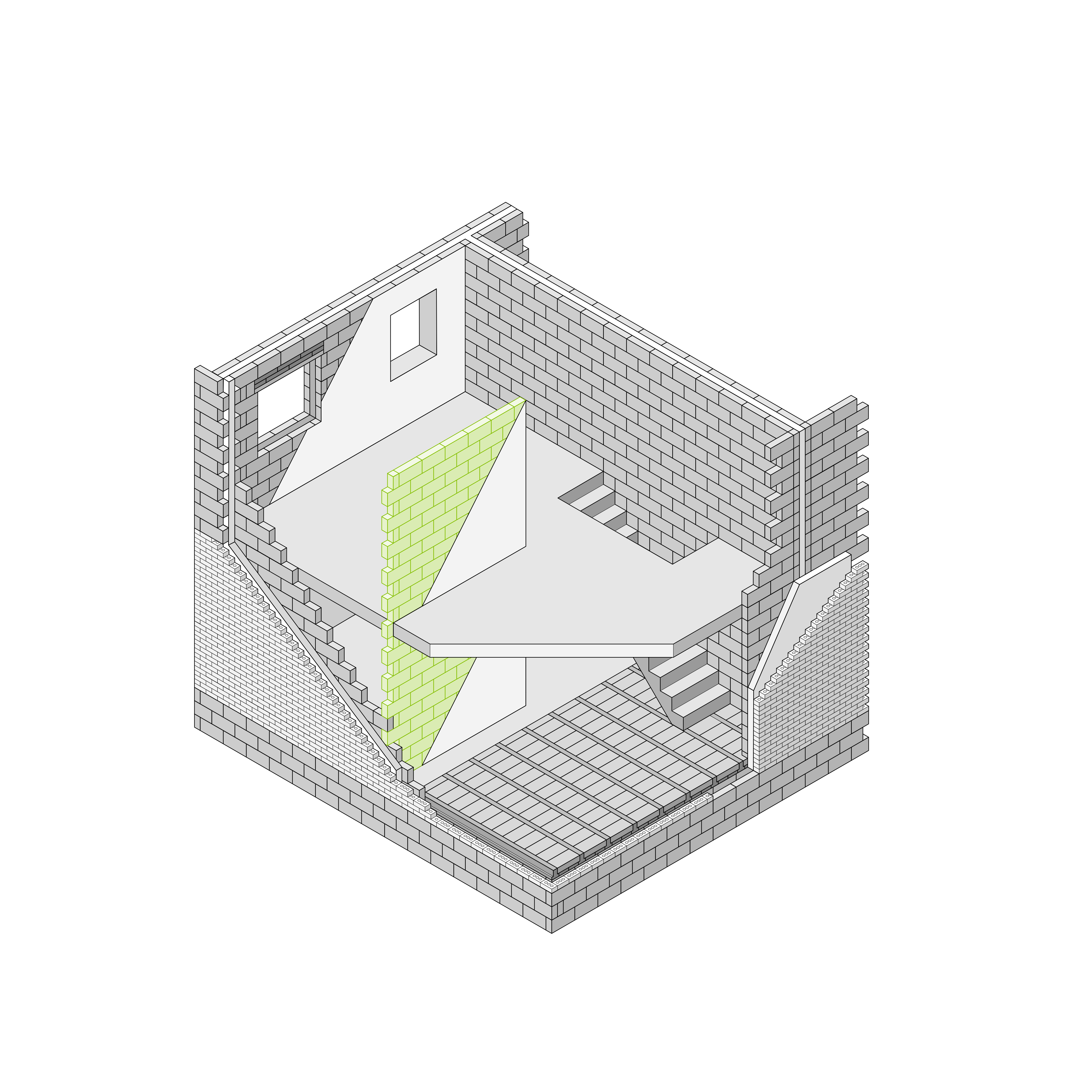

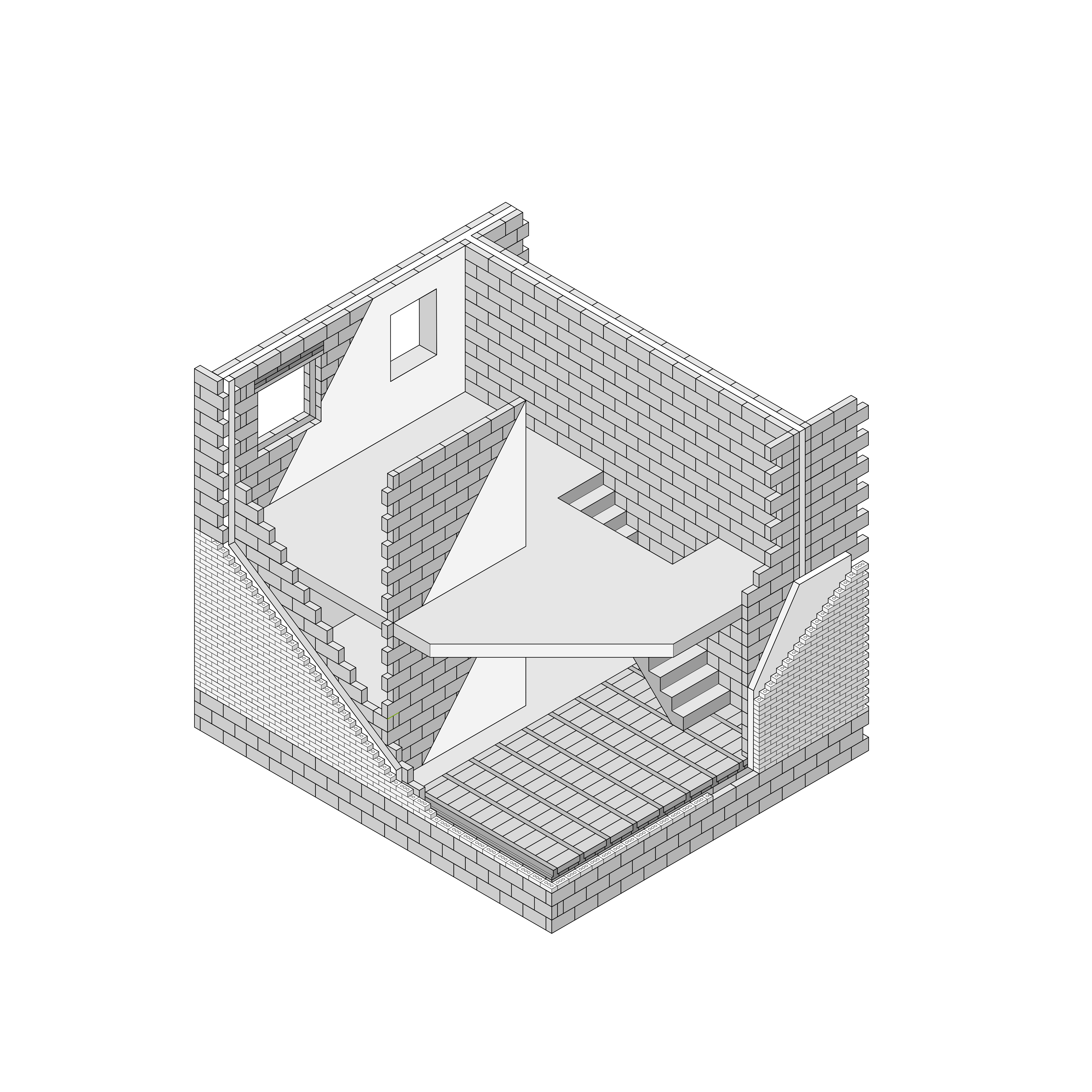

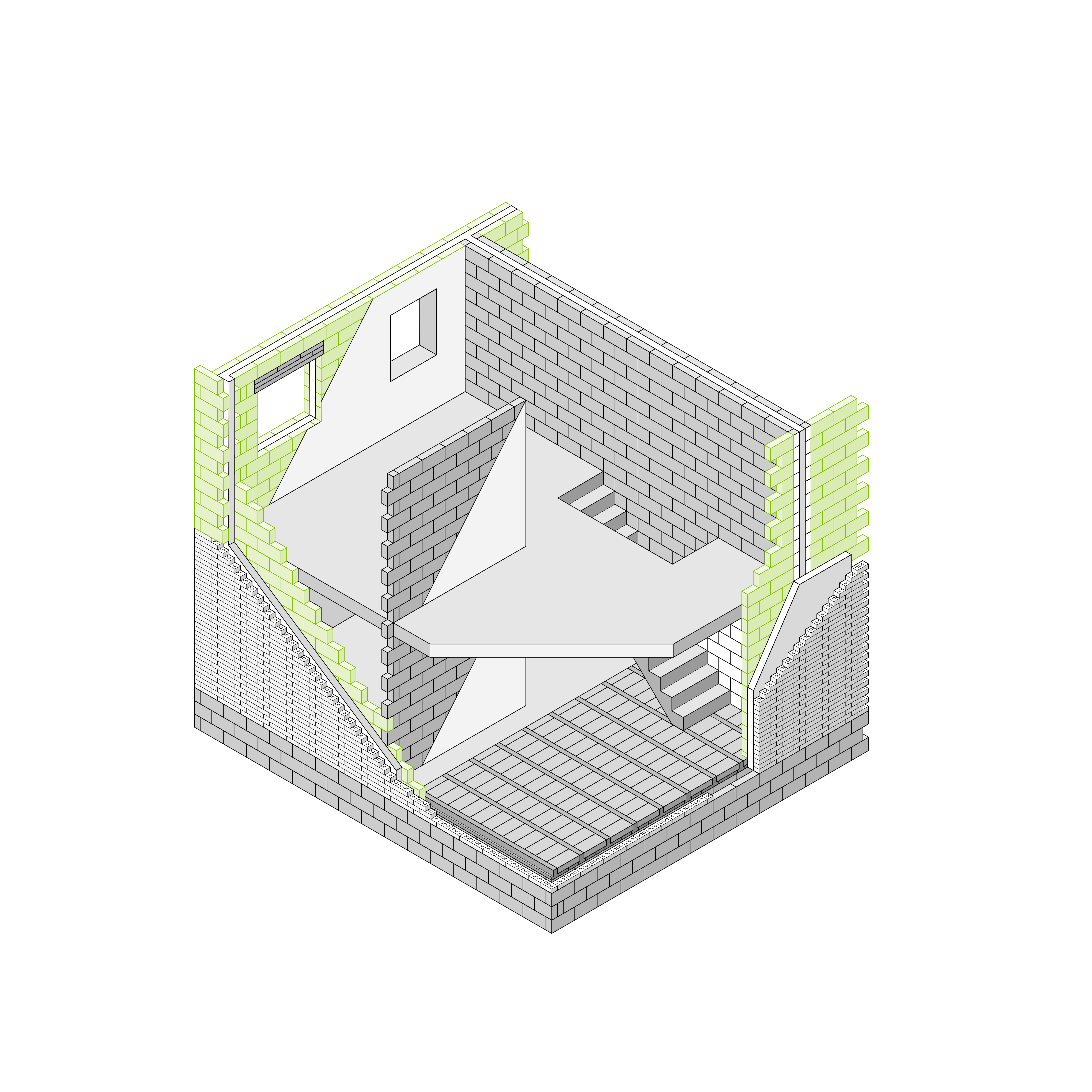

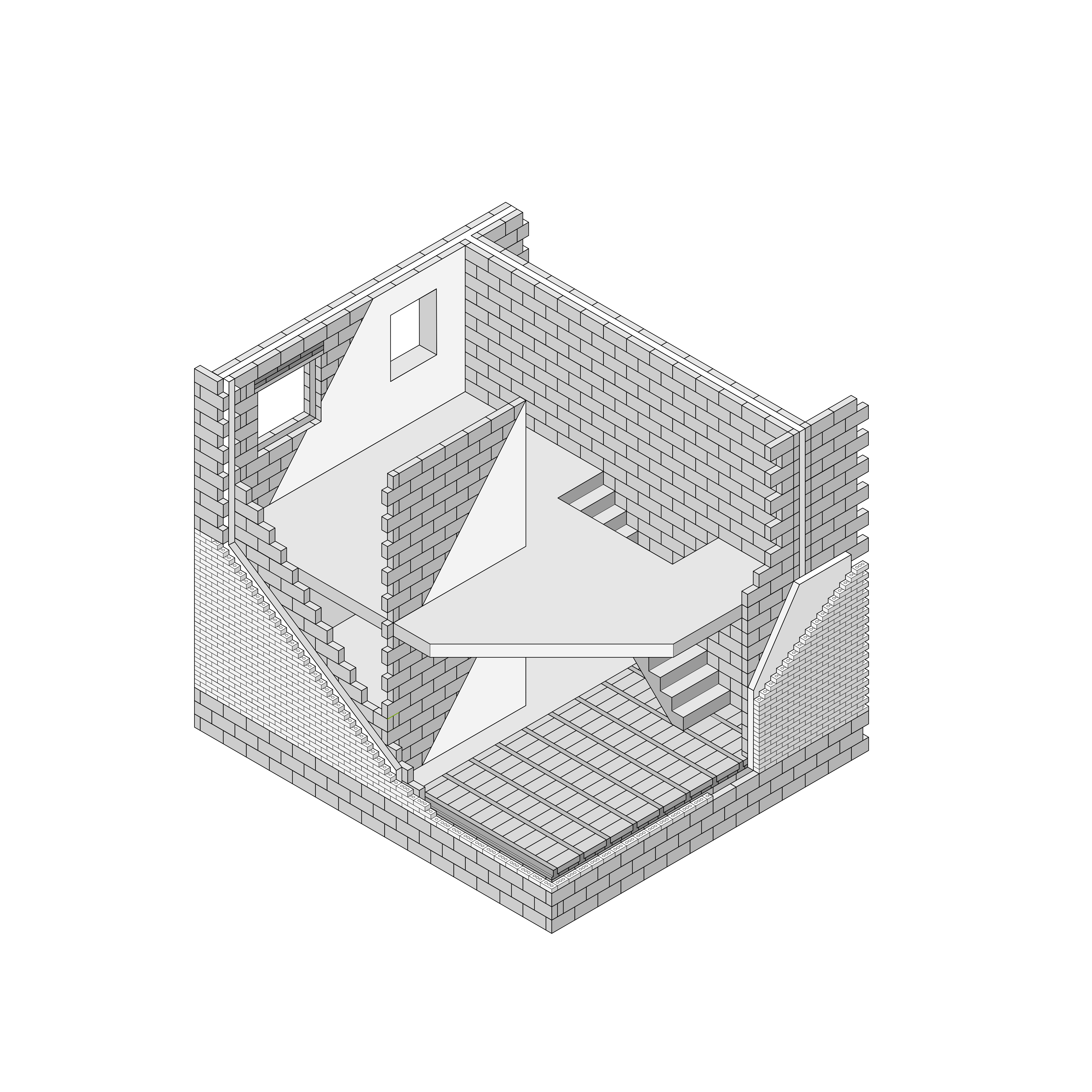

Domestic Housing

Information

Recommended Blocks: 1

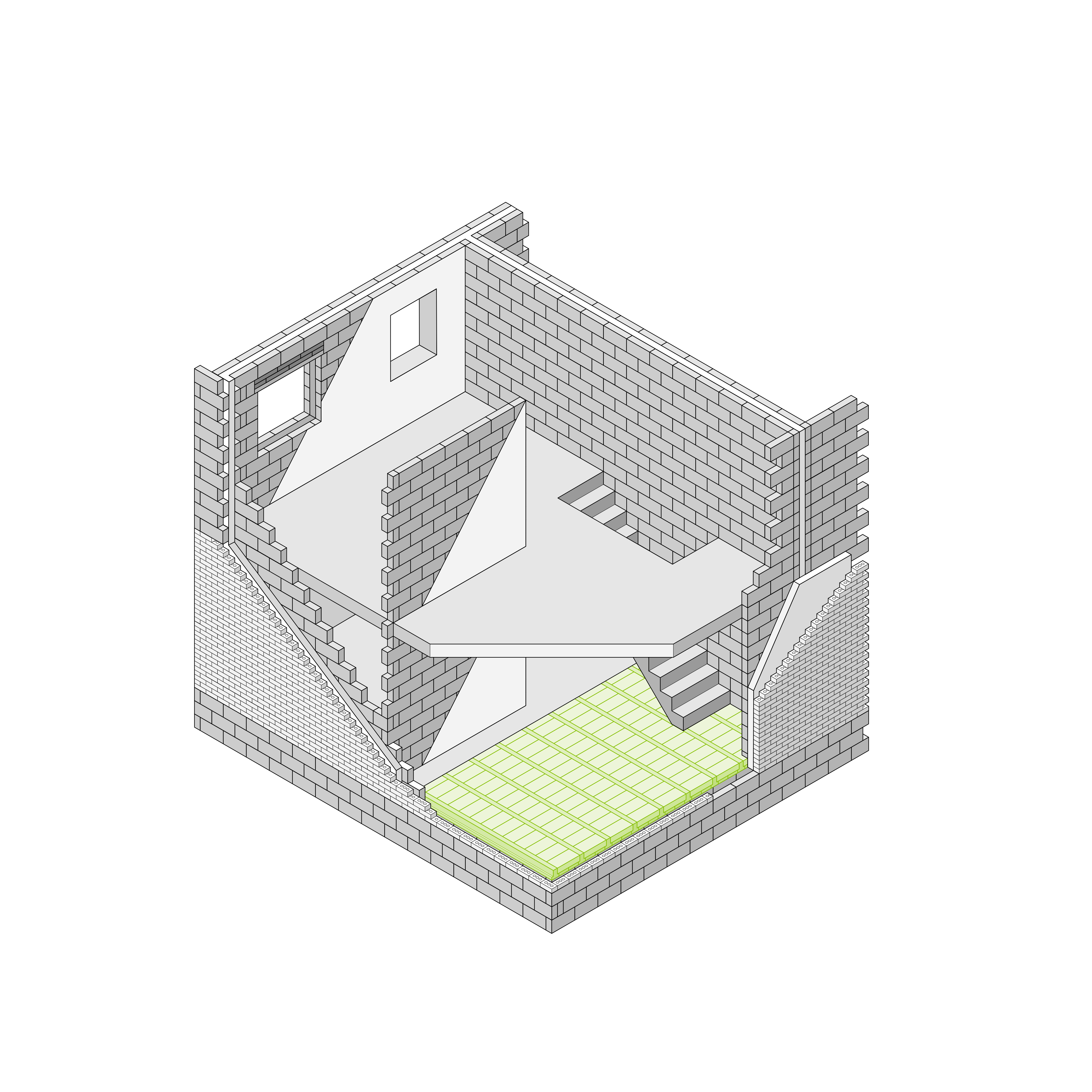

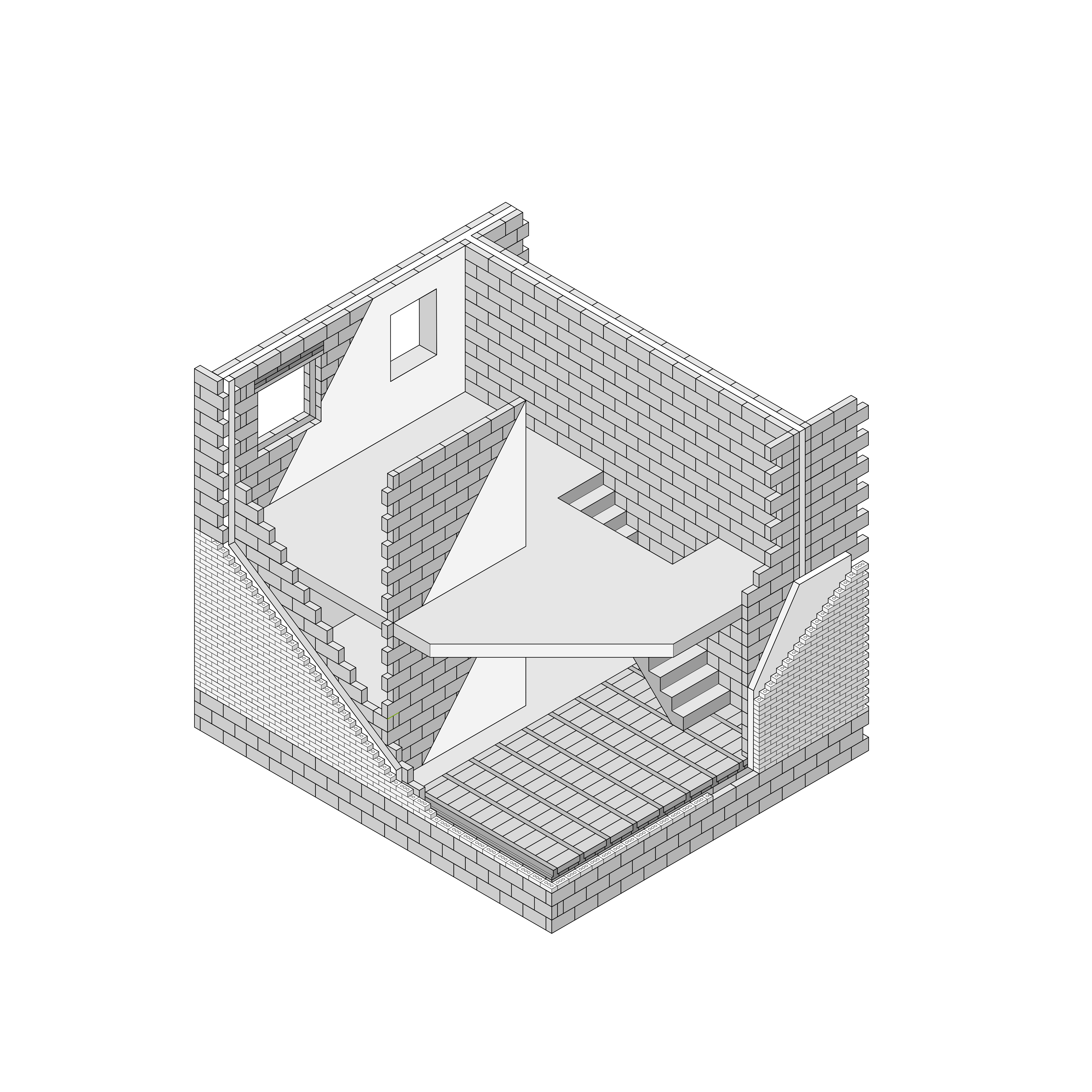

Other usesDomestic Housing

Domestic Housing

Information

Recommended Blocks: 3

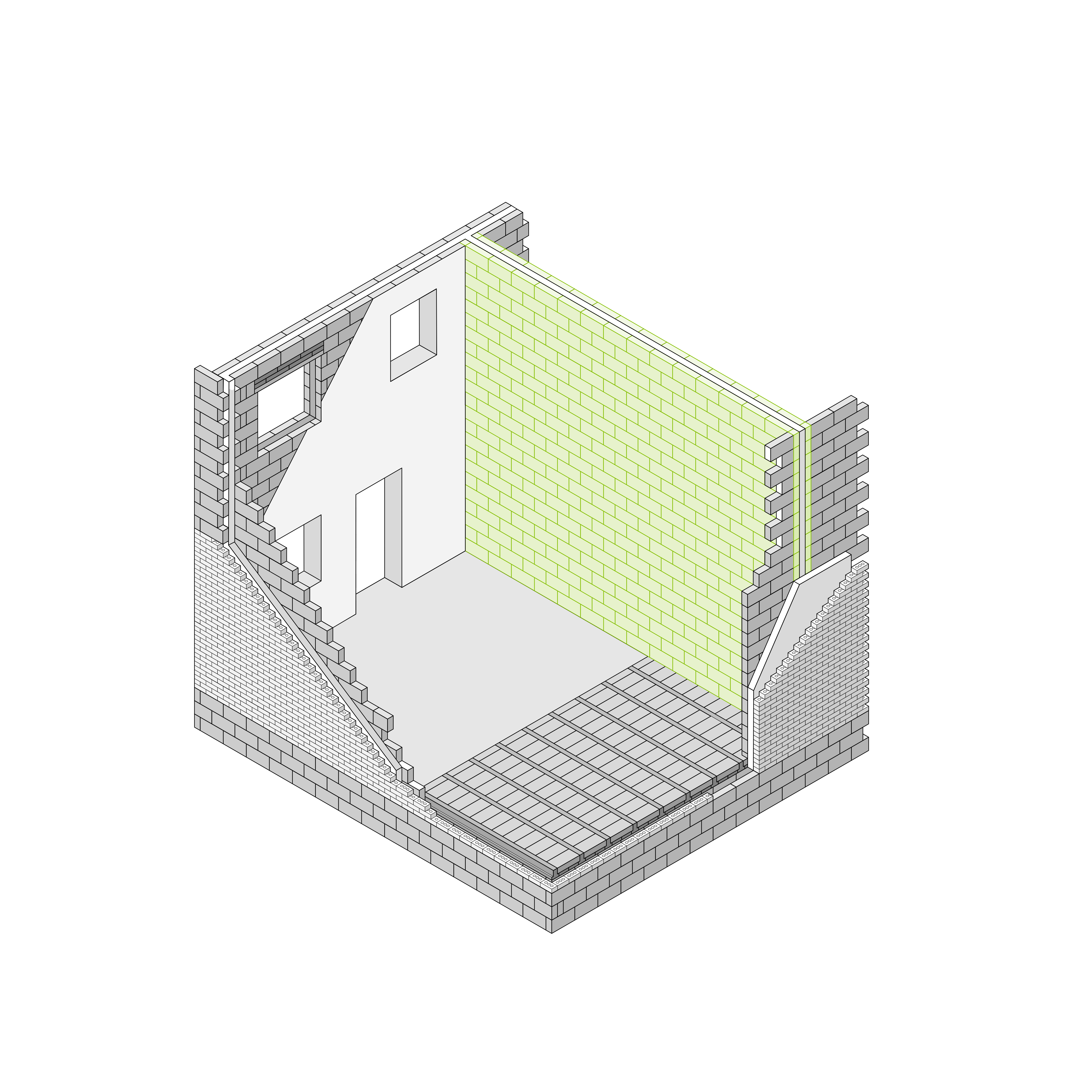

Other usesDomestic Housing

Domestic Housing

Information

Recommended Blocks: 3

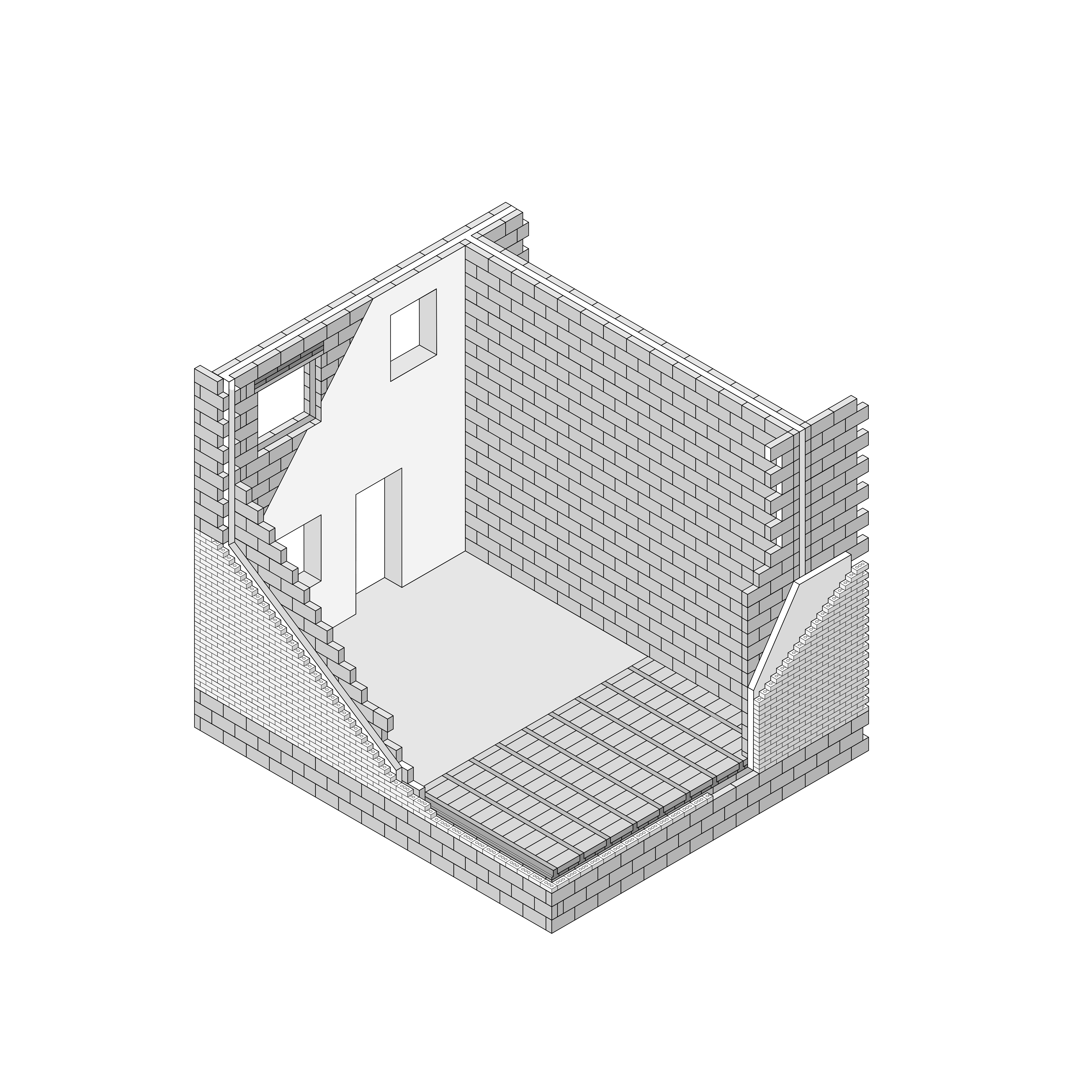

Other usesDomestic Housing

Domestic Housing

Information

Recommended Blocks: 2

Other usesDomestic Housing

Domestic Housing

Information

Recommended Blocks: 2

Other usesDomestic Housing

Domestic Housing

Information

Recommended Blocks: 3

Other buildings

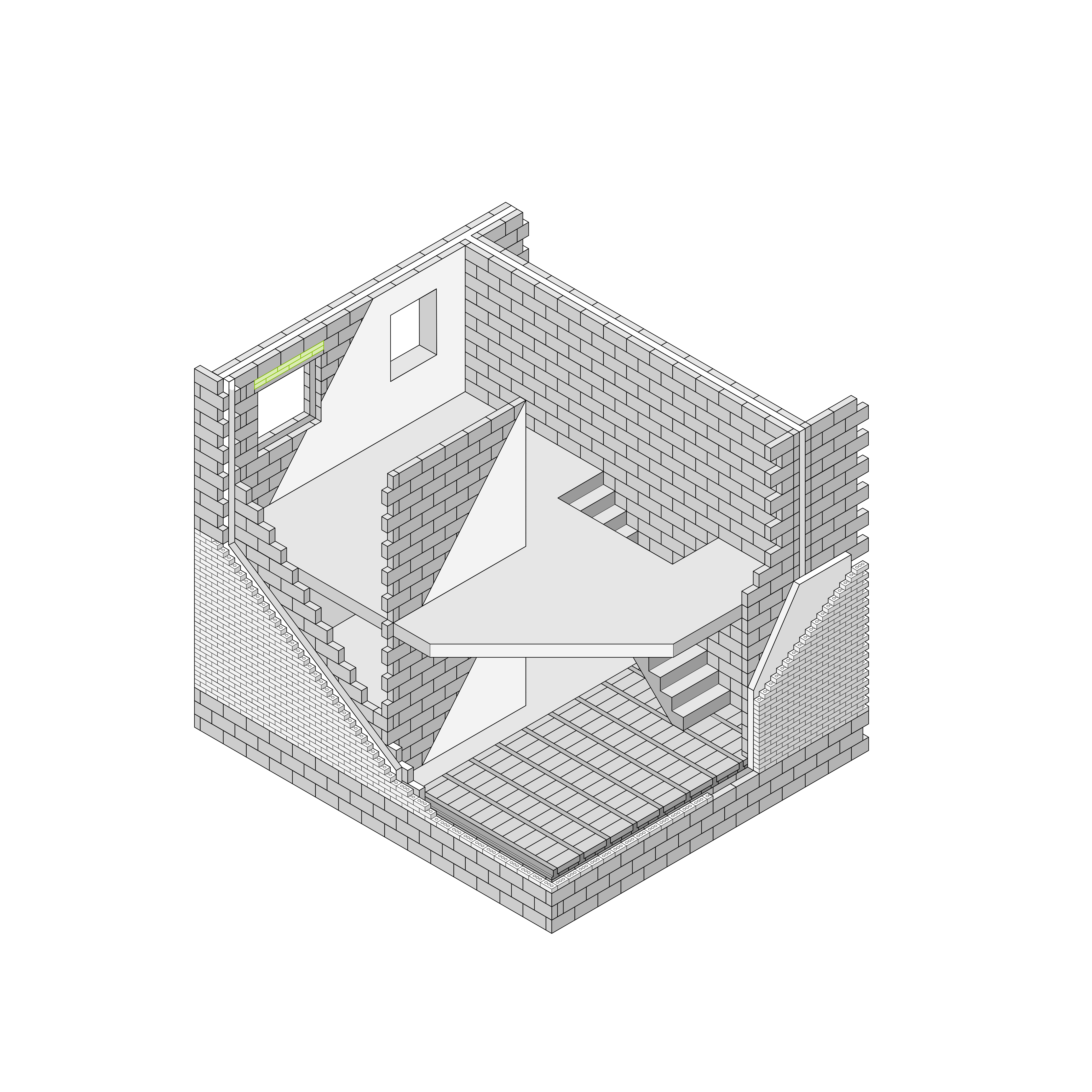

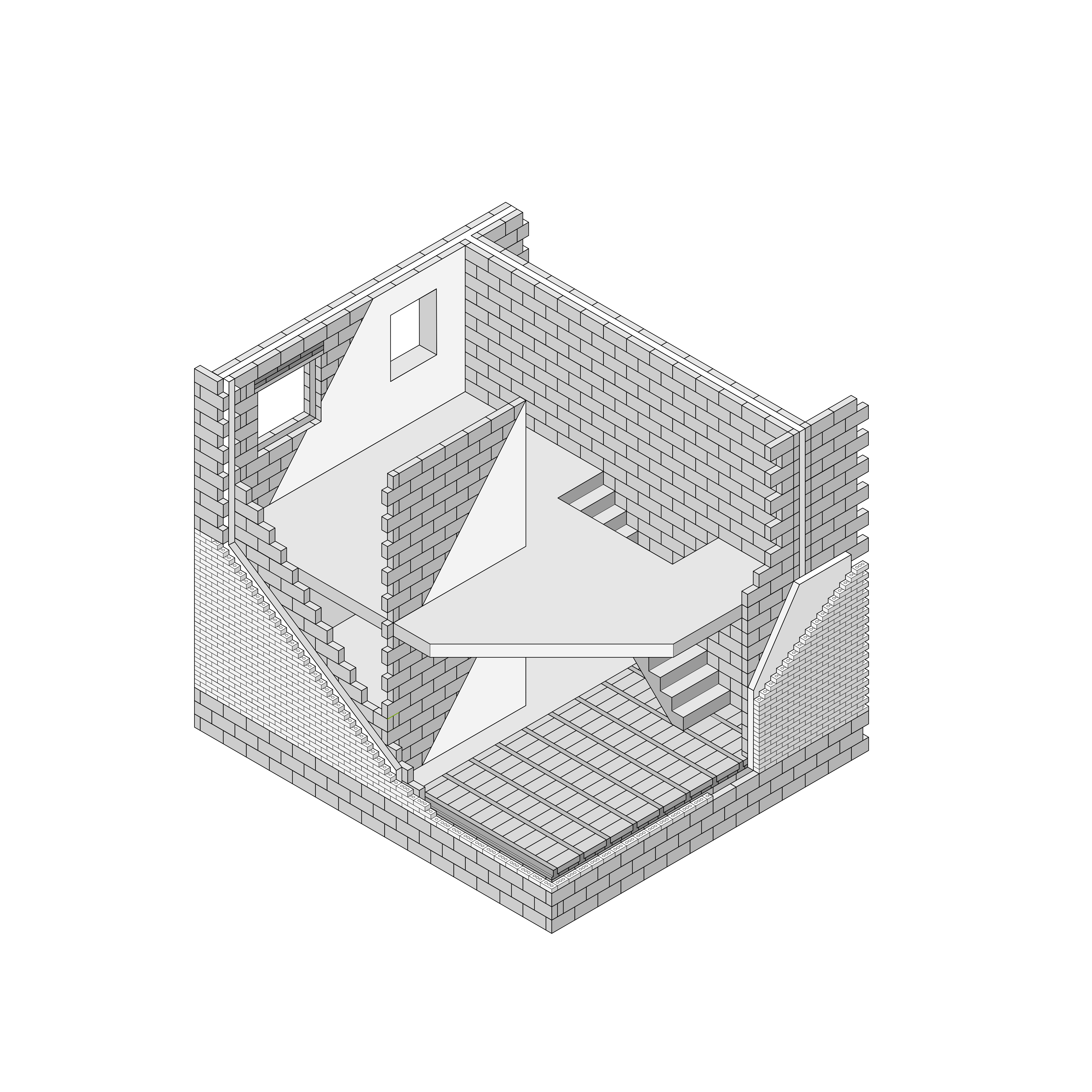

Domestic Housing

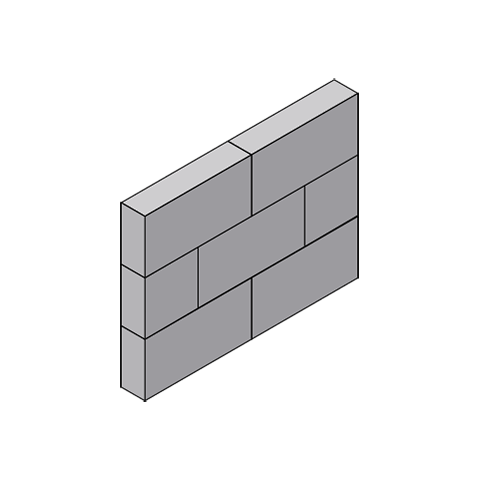

- 1 Blocks Below Ground

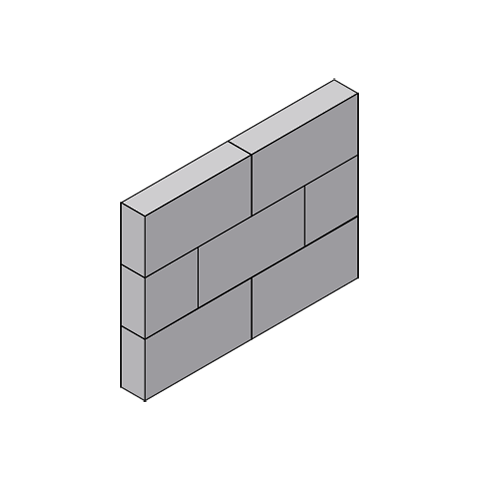

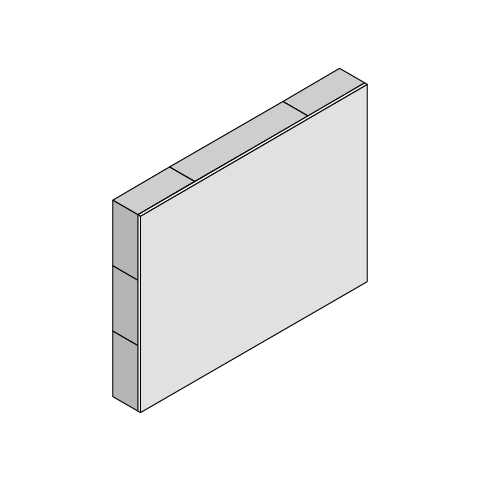

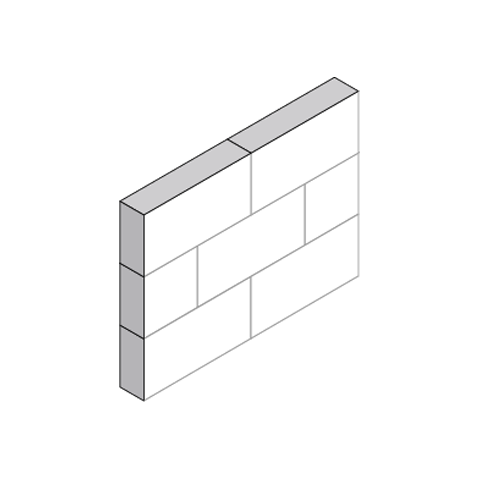

- 2 Party Walls

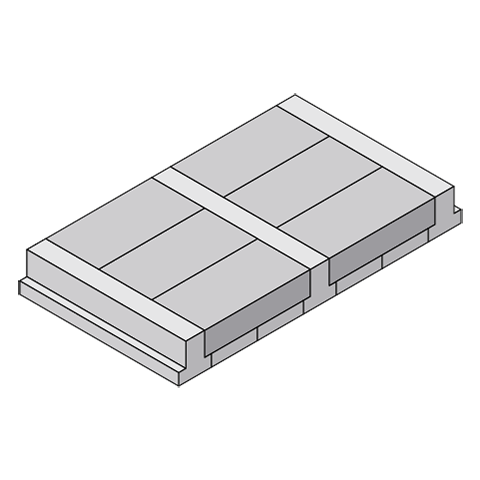

- 3 Beam and Block Floors

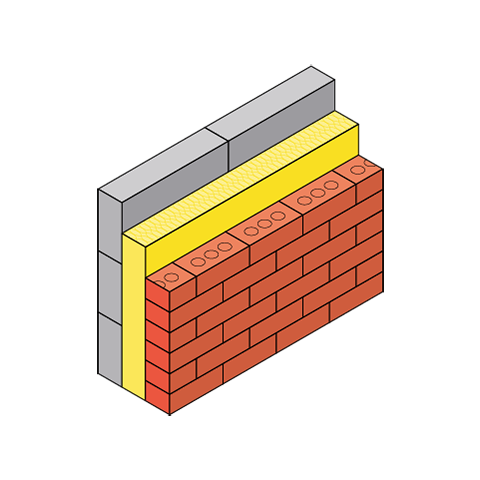

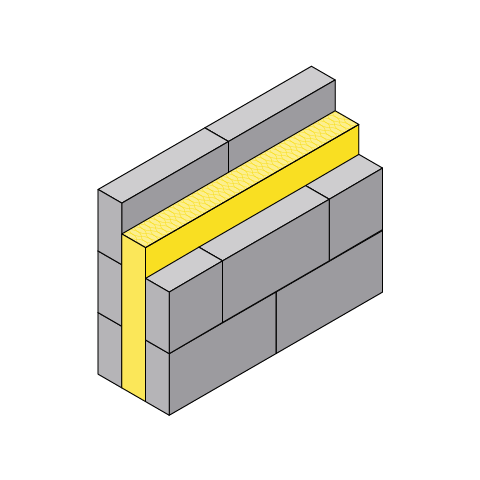

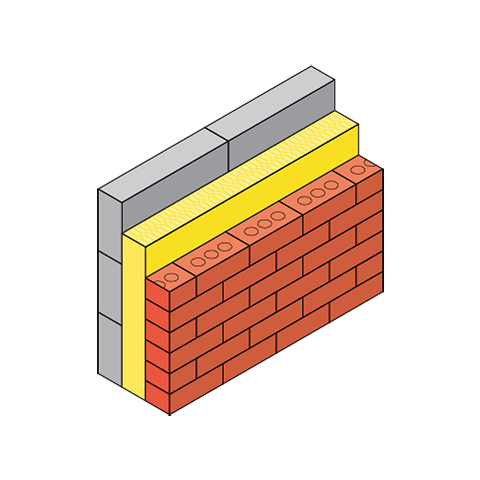

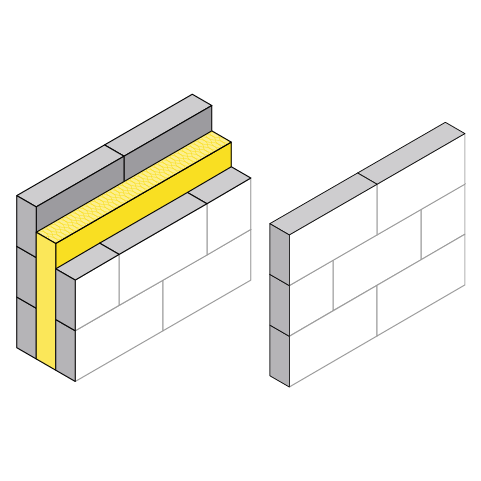

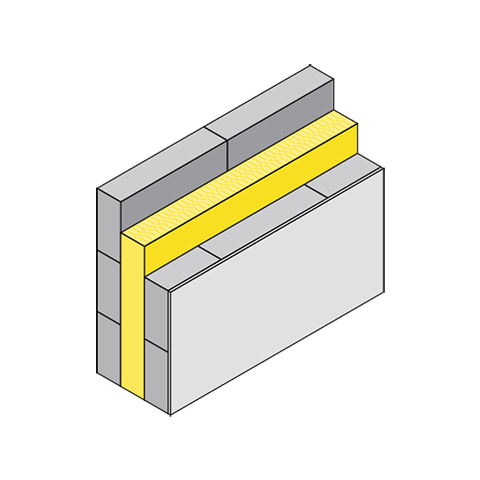

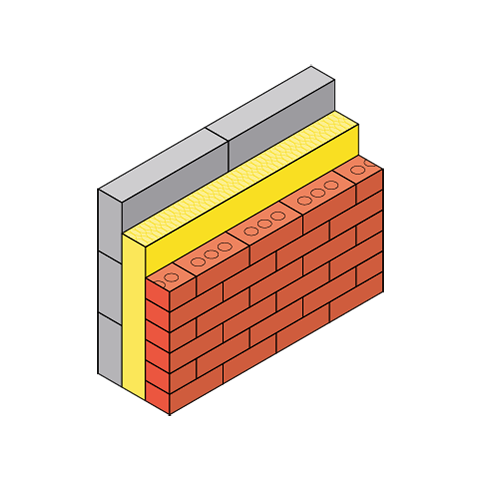

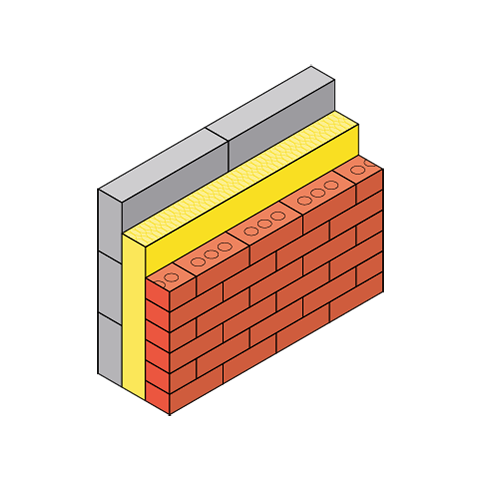

- 4 Facing Brick (or Render) Cavity Walls

- 5 Partition Walls

- 6 Coursing Blocks

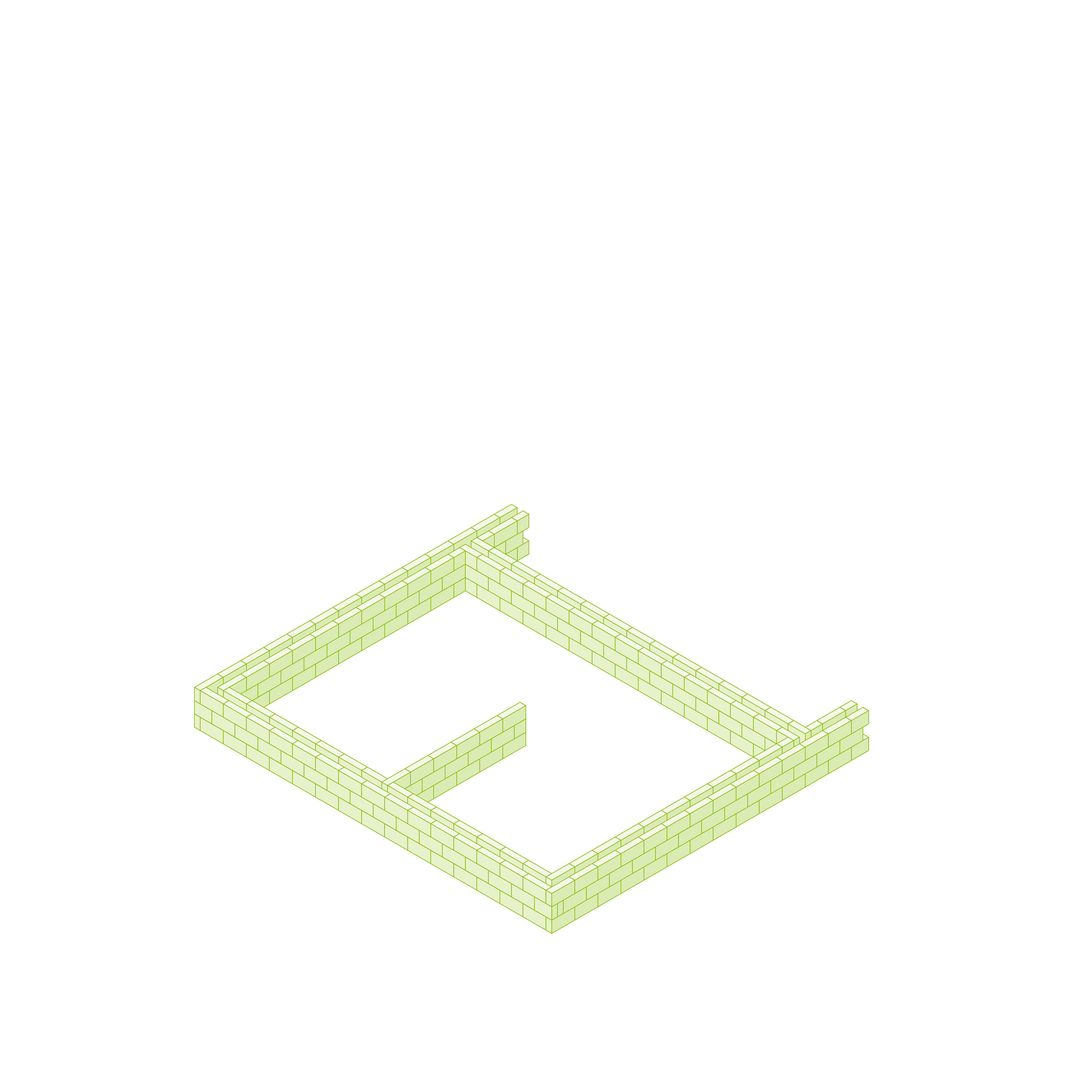

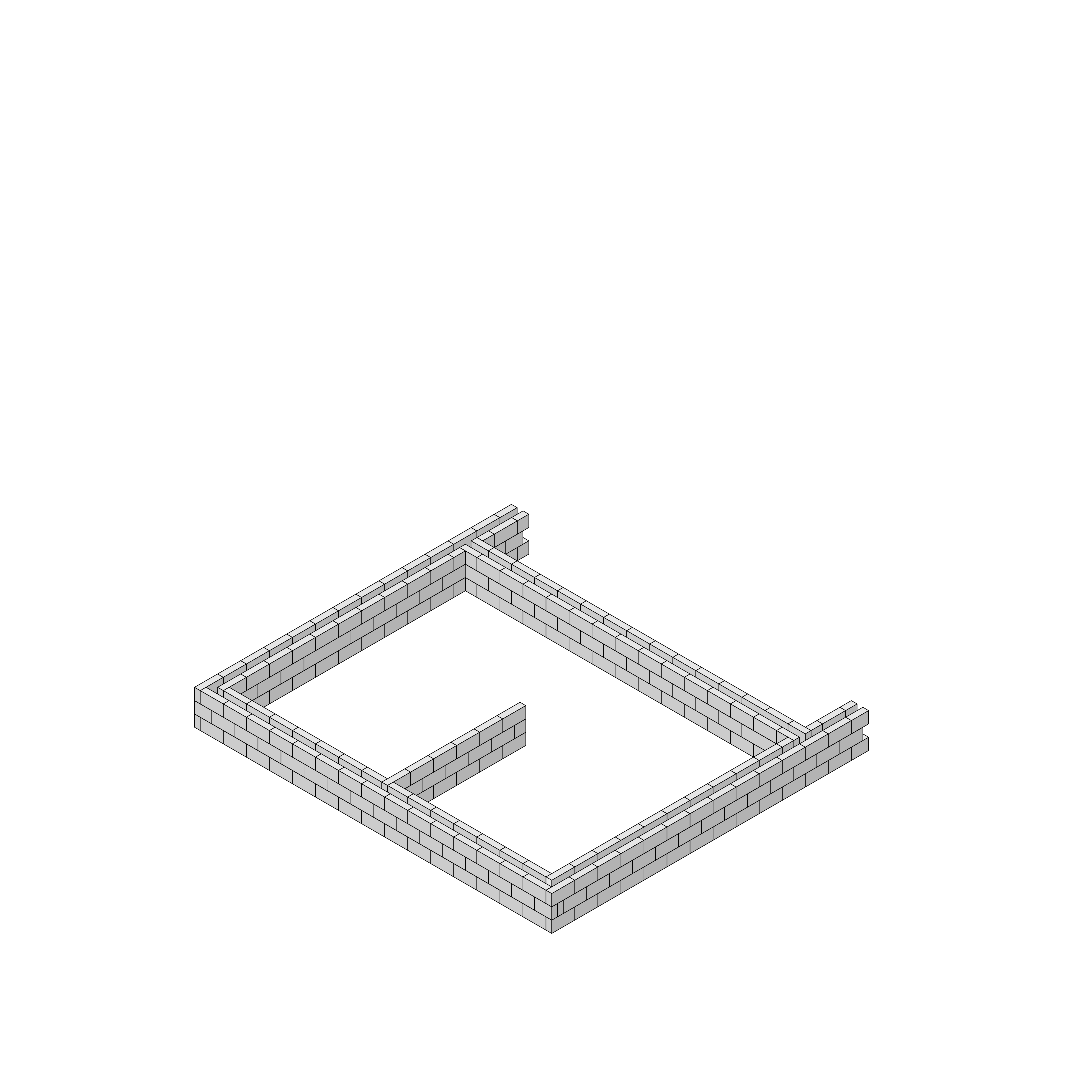

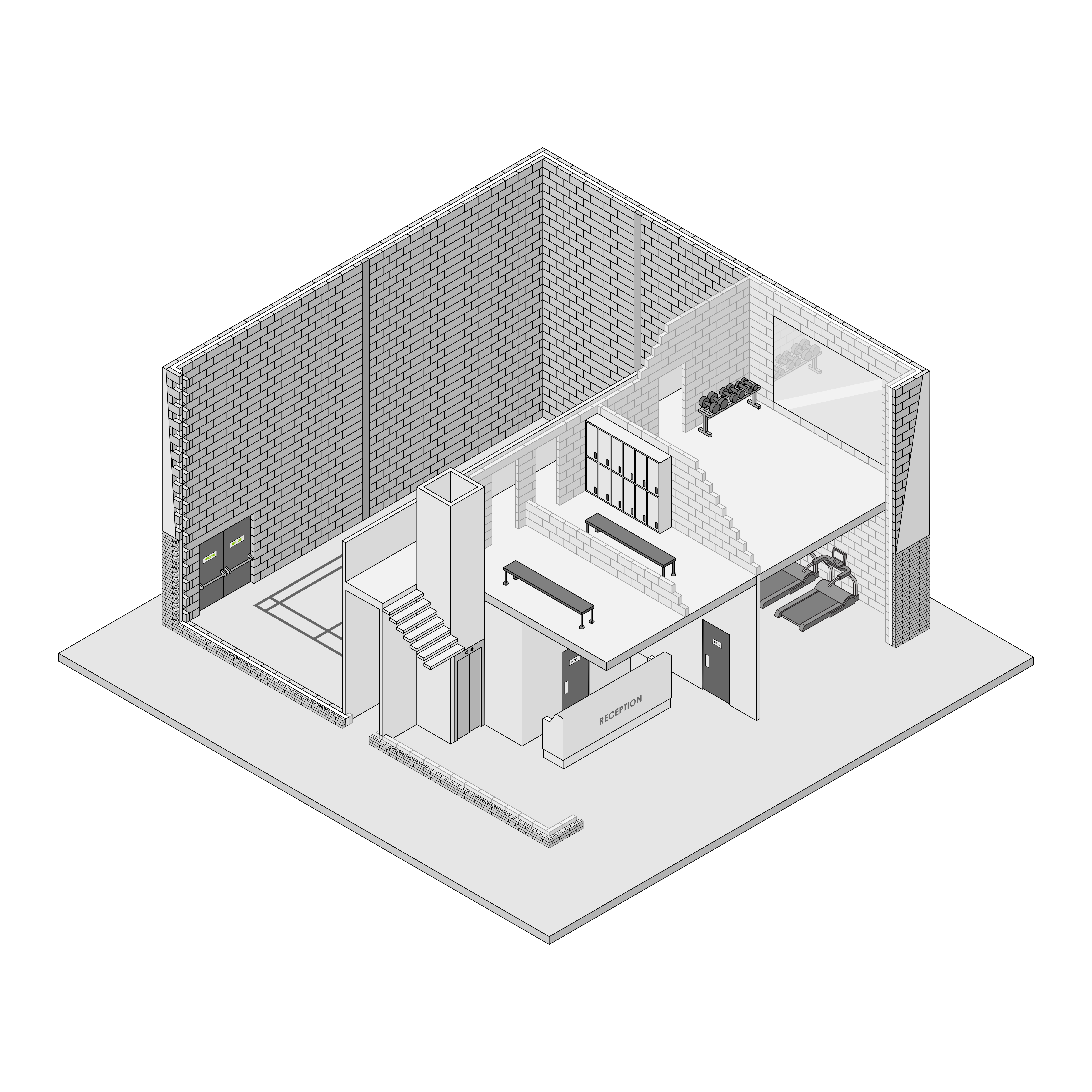

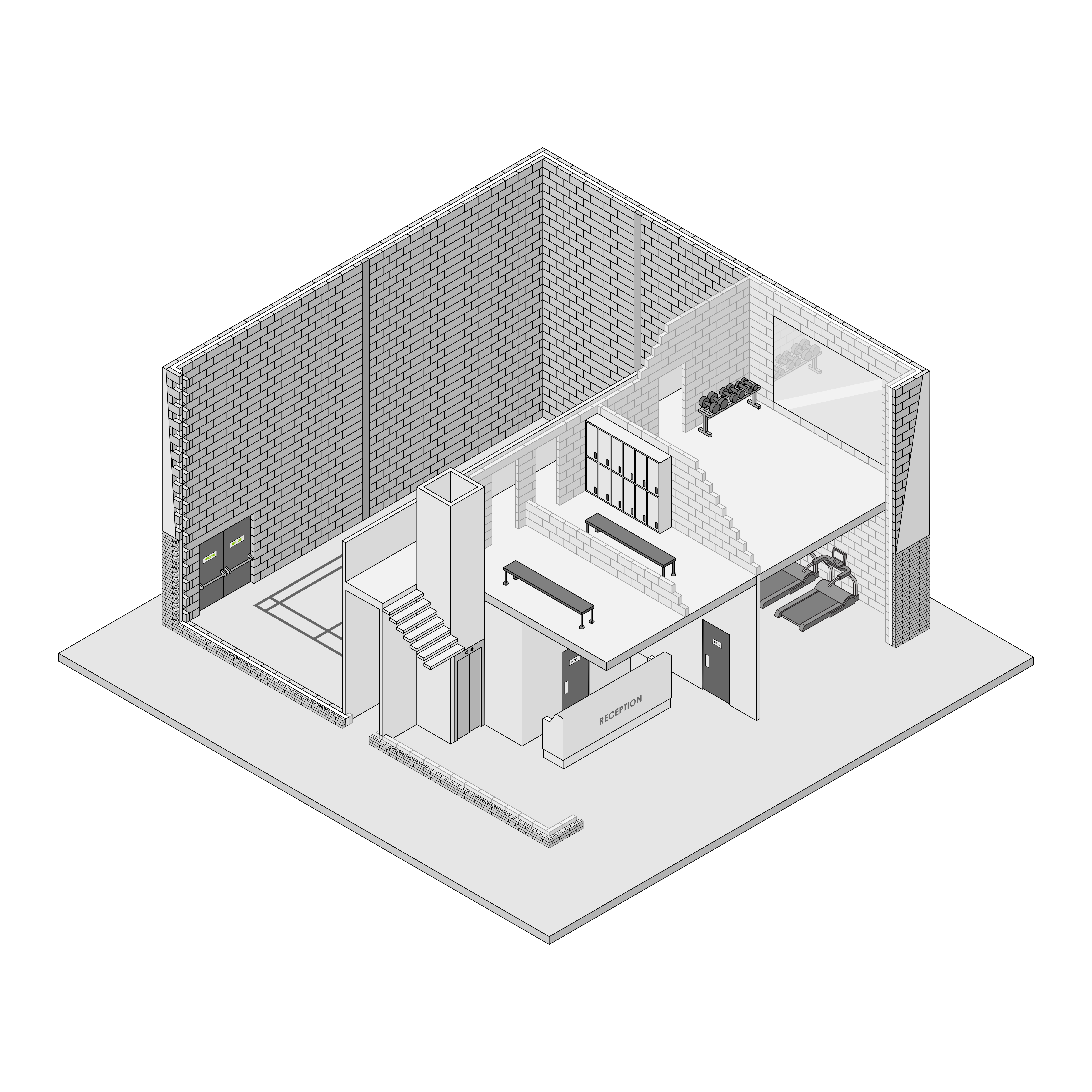

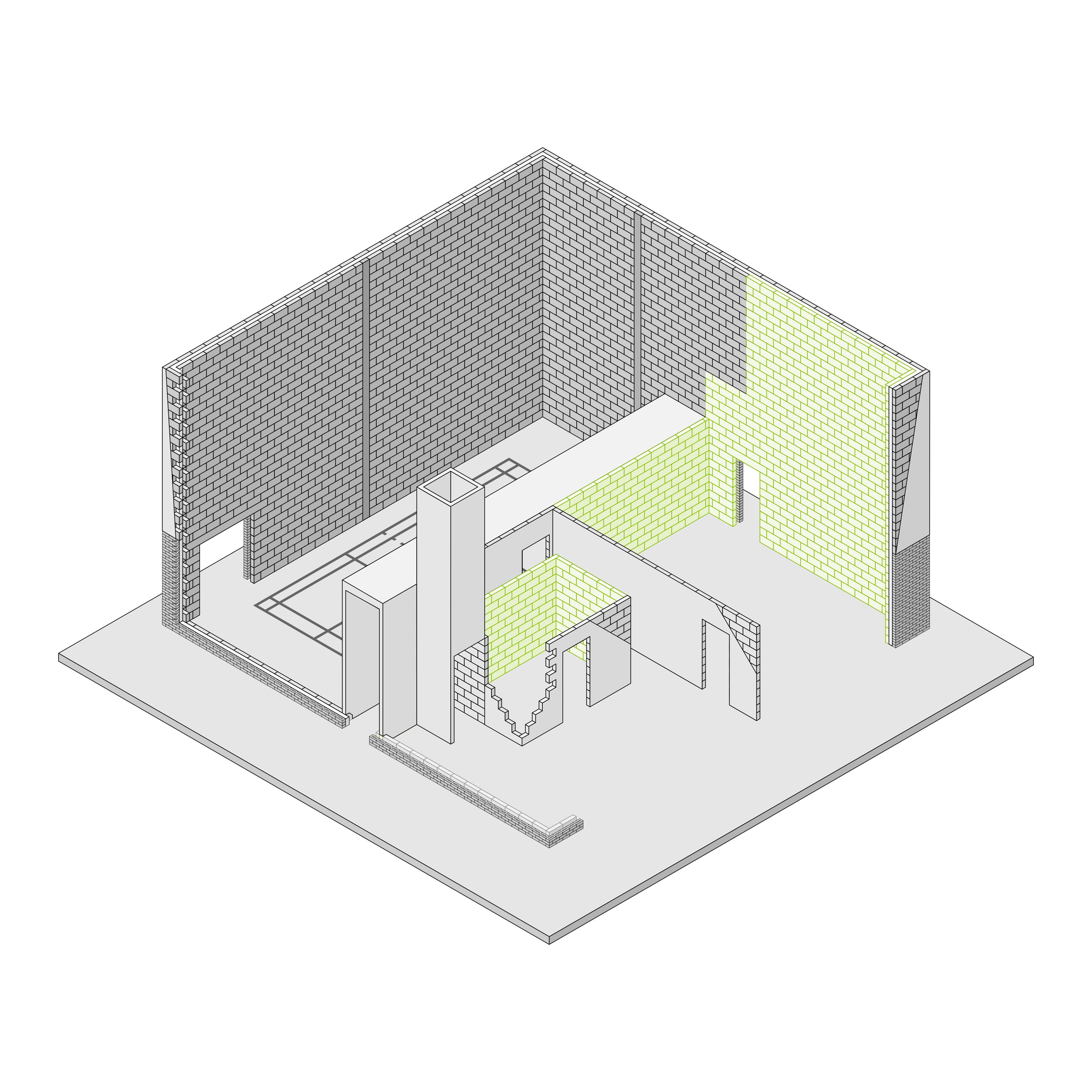

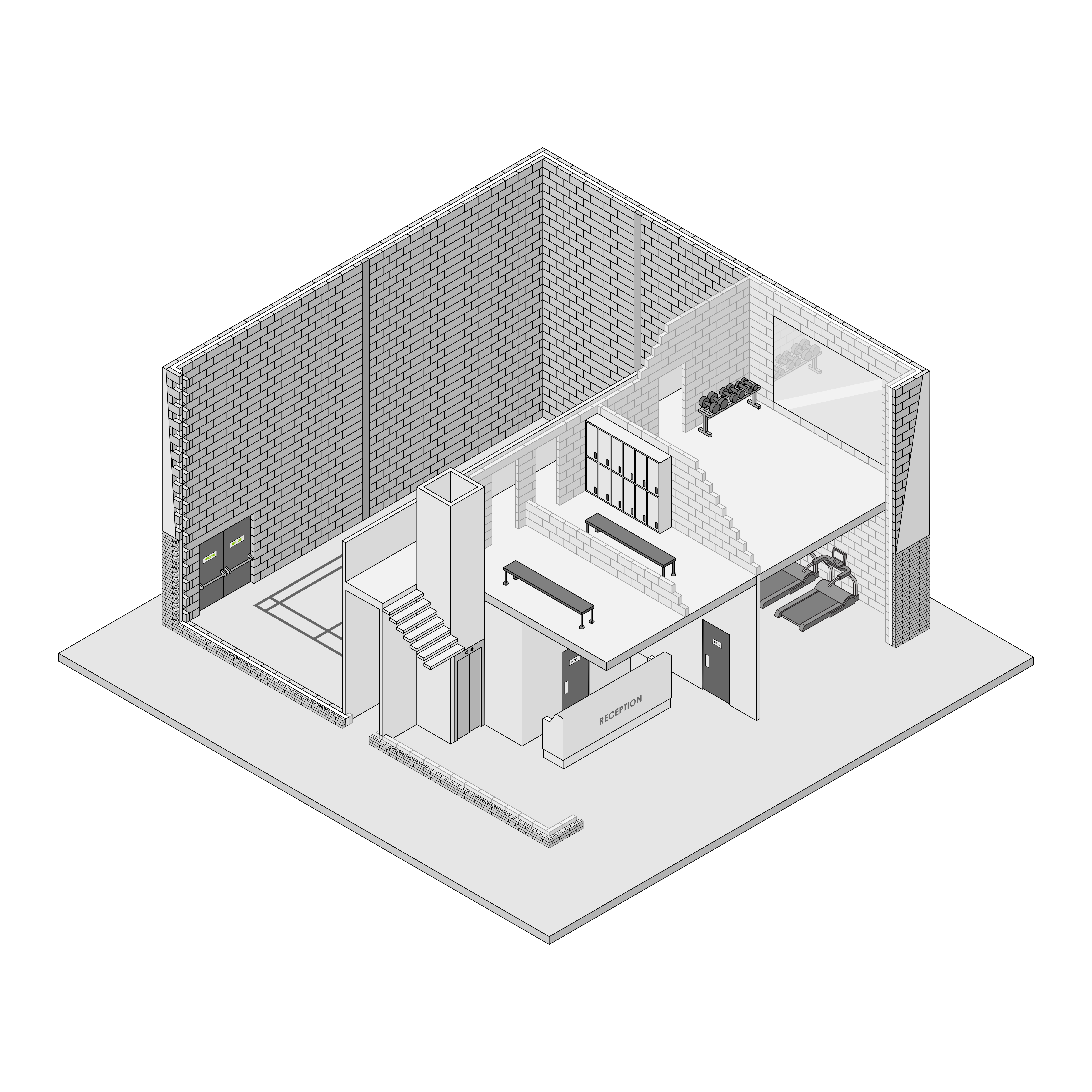

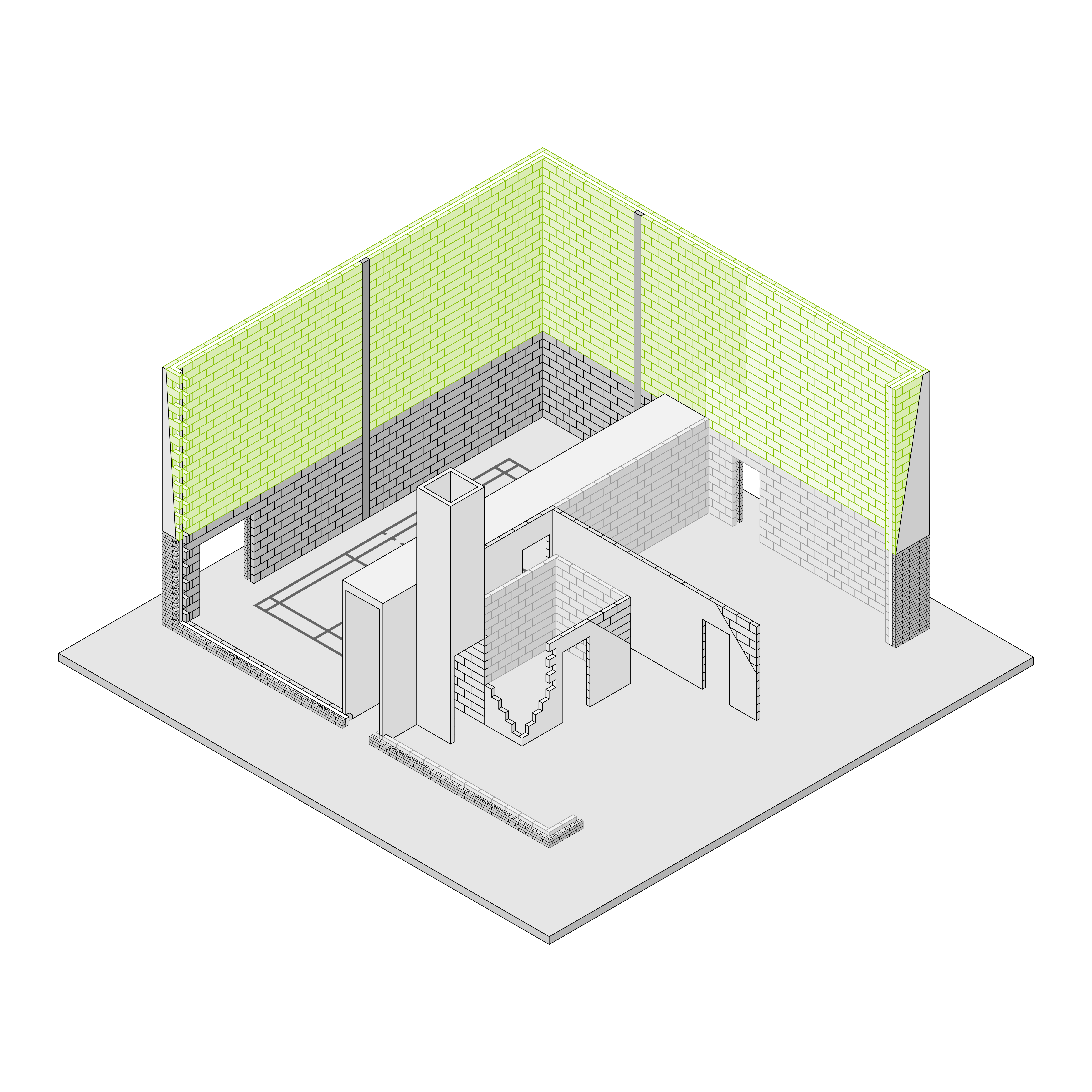

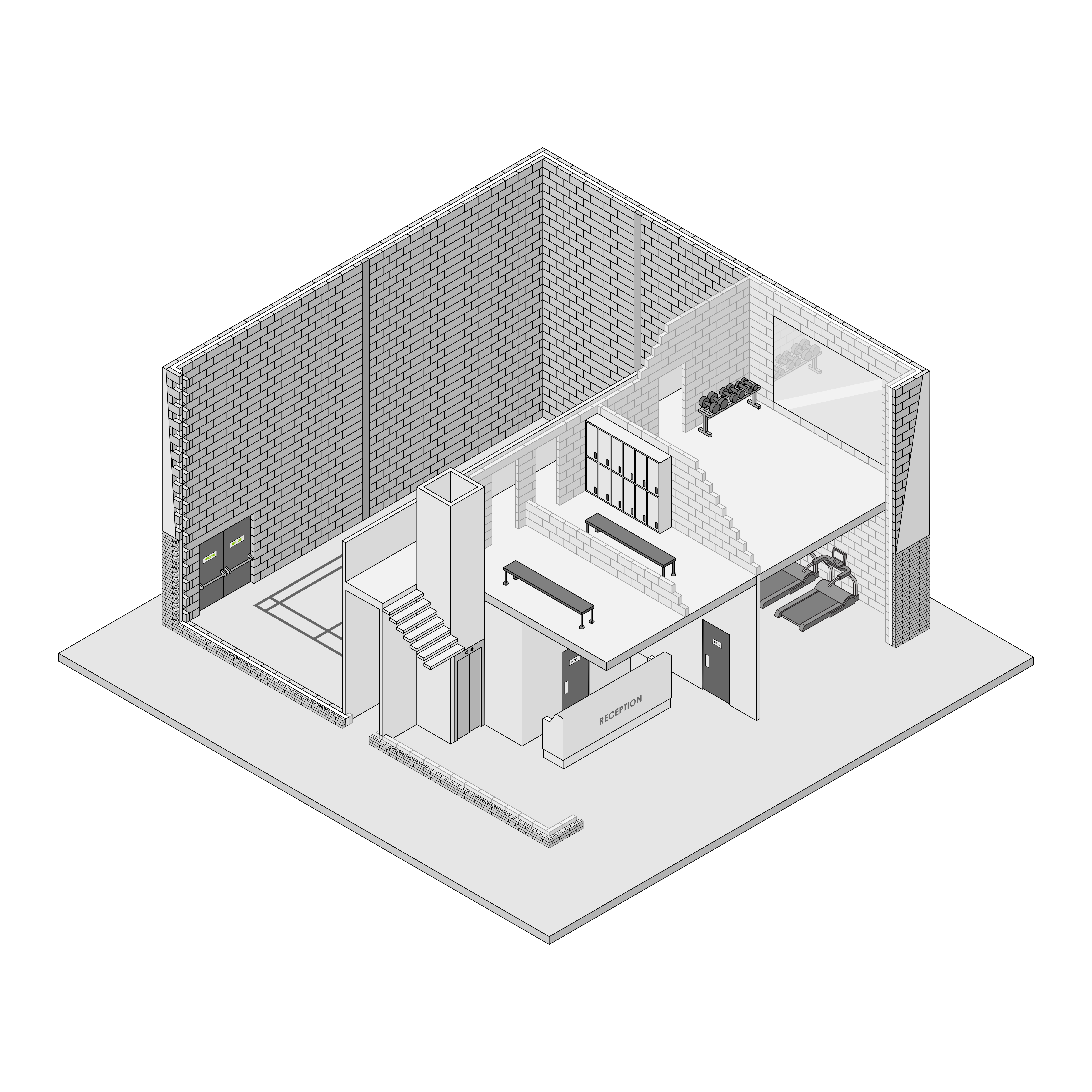

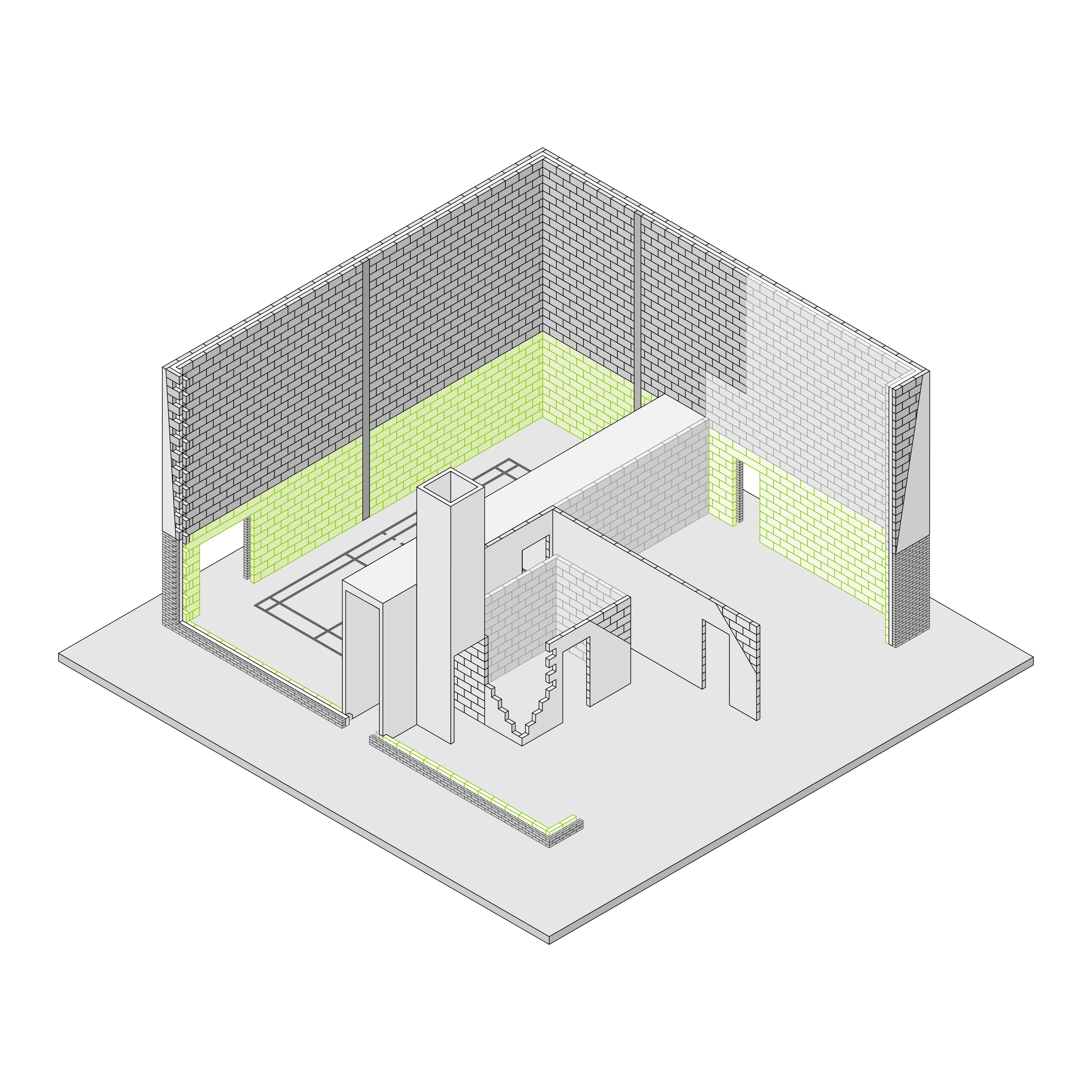

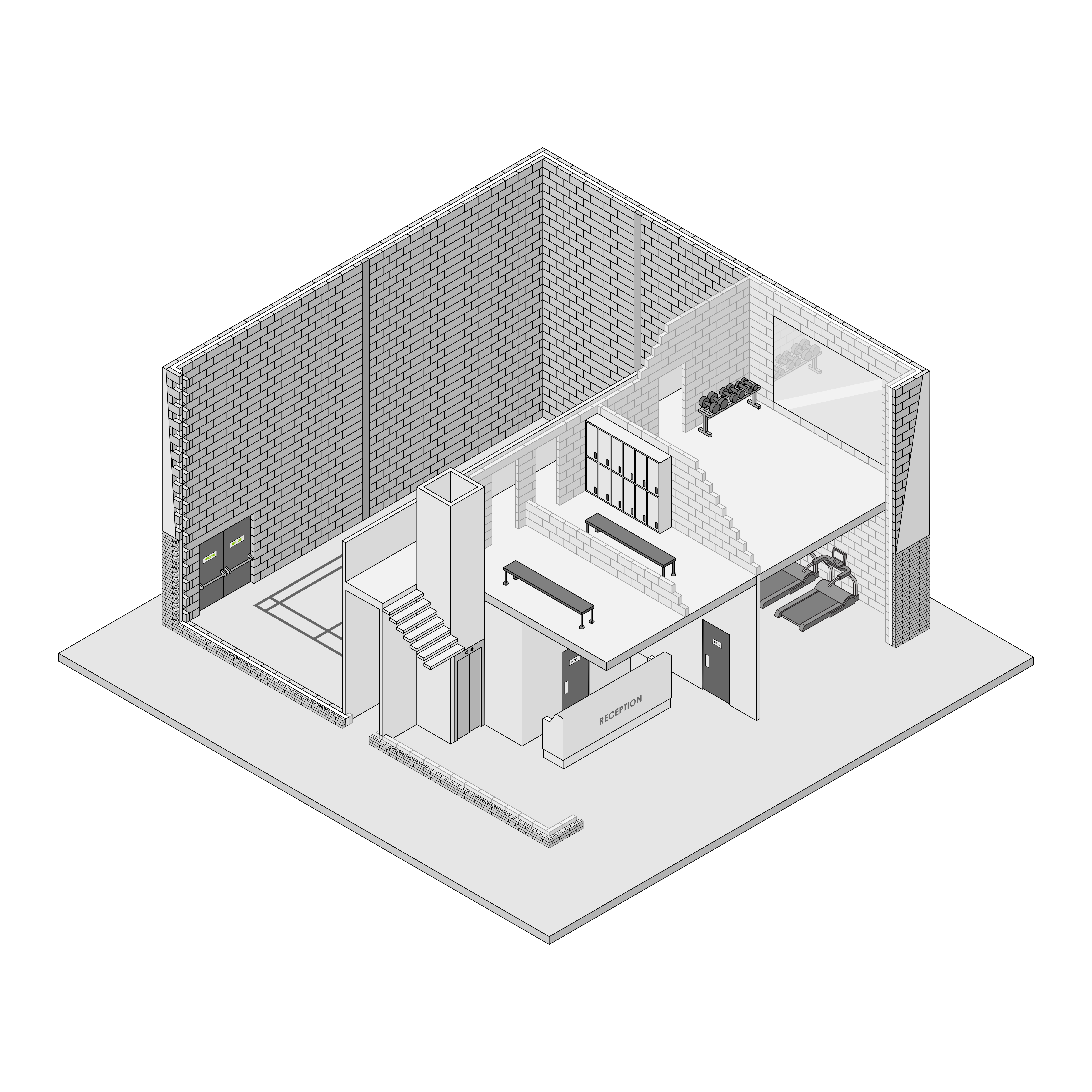

Other usesLeisure Centre

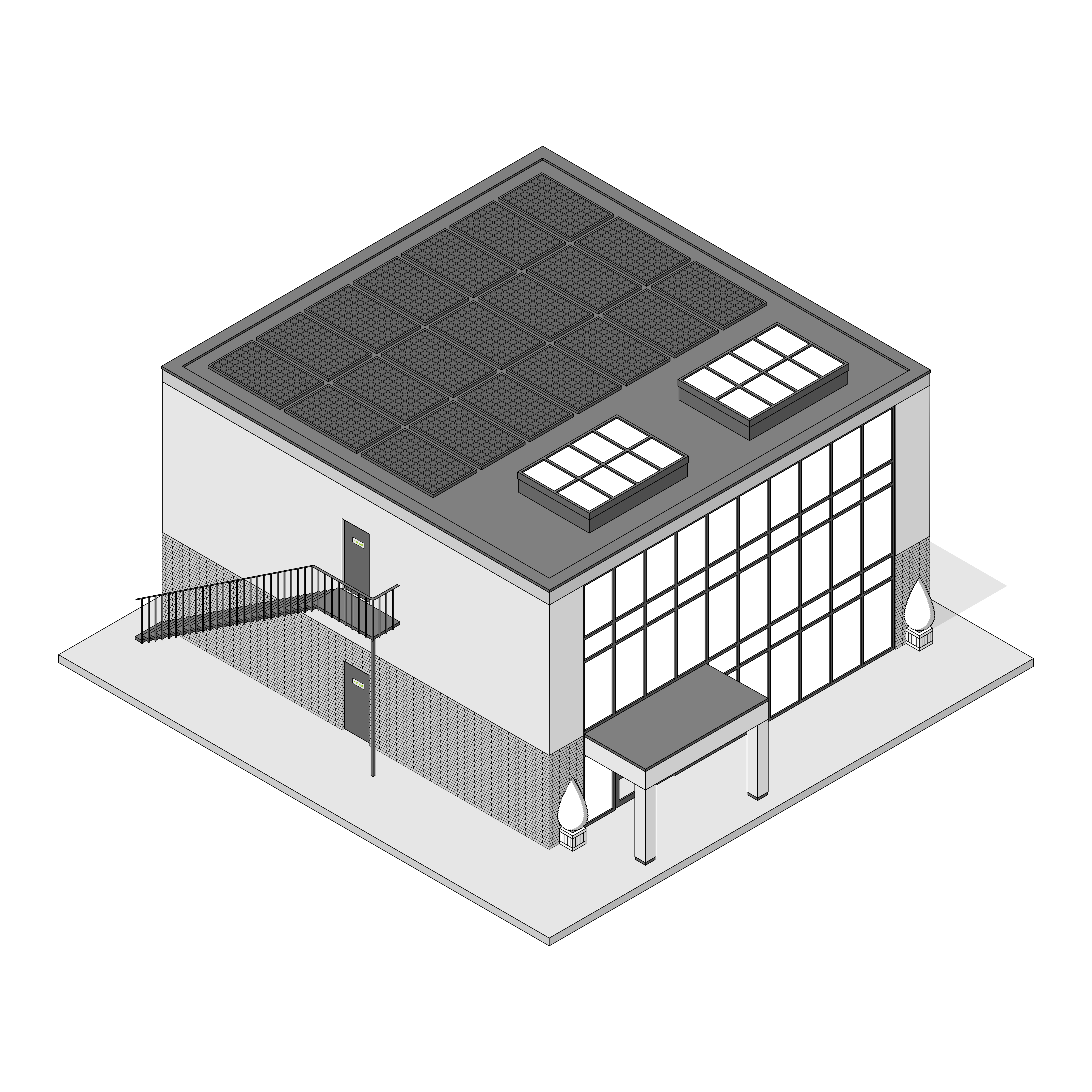

Leisure Centre

Information

Recommended Blocks: 3

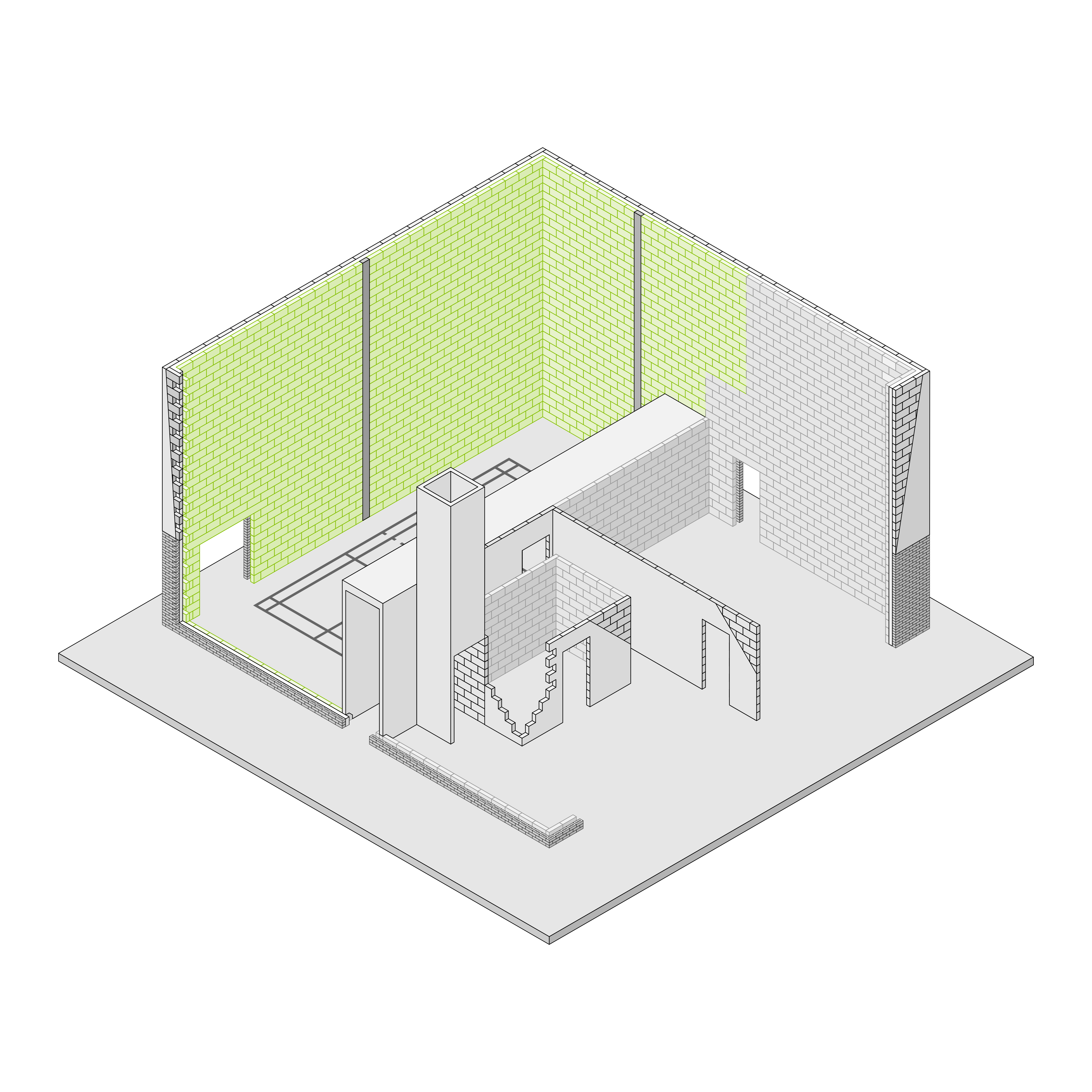

Other usesLeisure Centre

Leisure Centre

Information

Recommended Blocks: 1

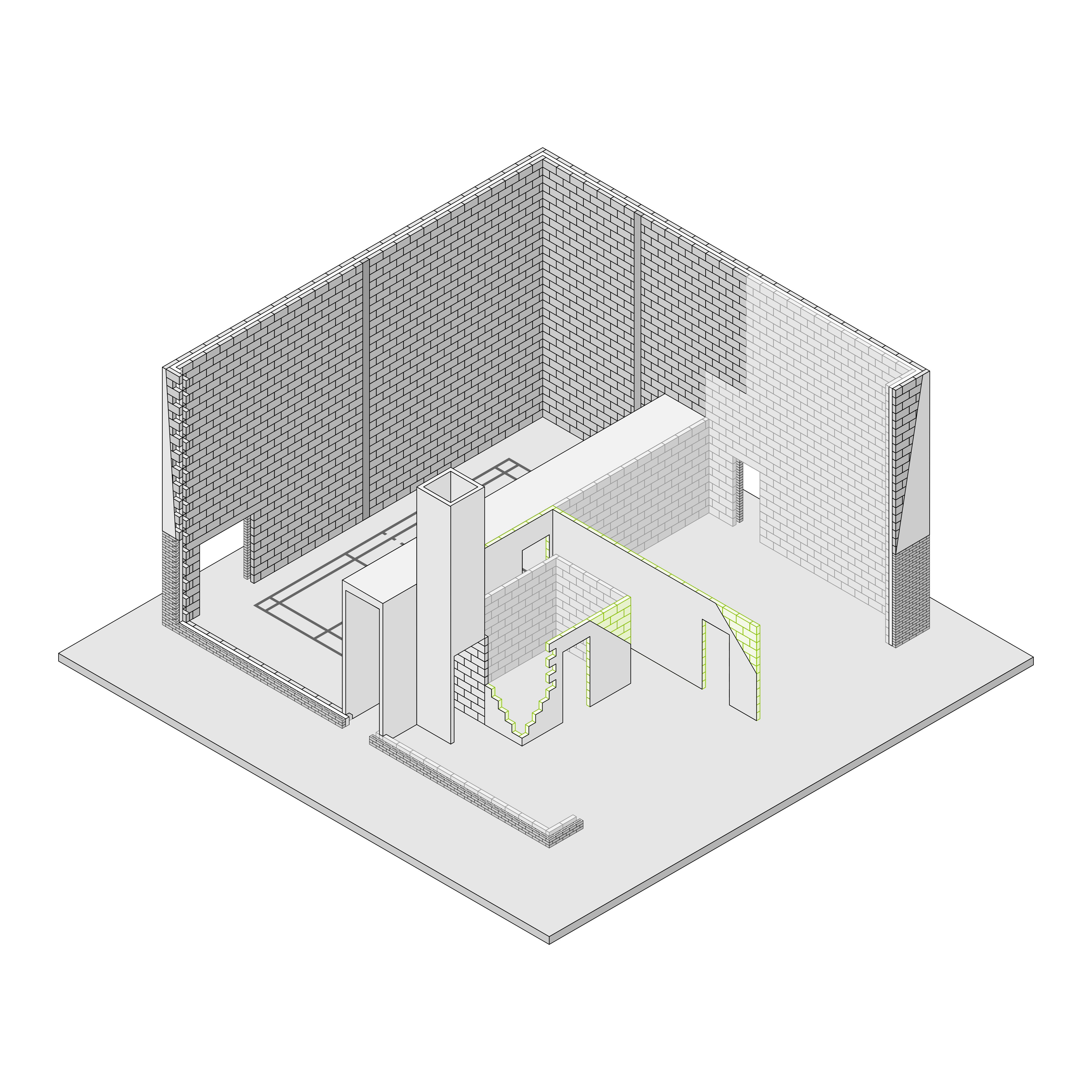

Other usesLeisure Centre

Leisure Centre

Information

Recommended Blocks: 2

Other usesLeisure Centre

Leisure Centre

Information

Recommended Blocks: 3

Other usesLeisure Centre

Leisure Centre

Information

Recommended Blocks: 5

Other buildings

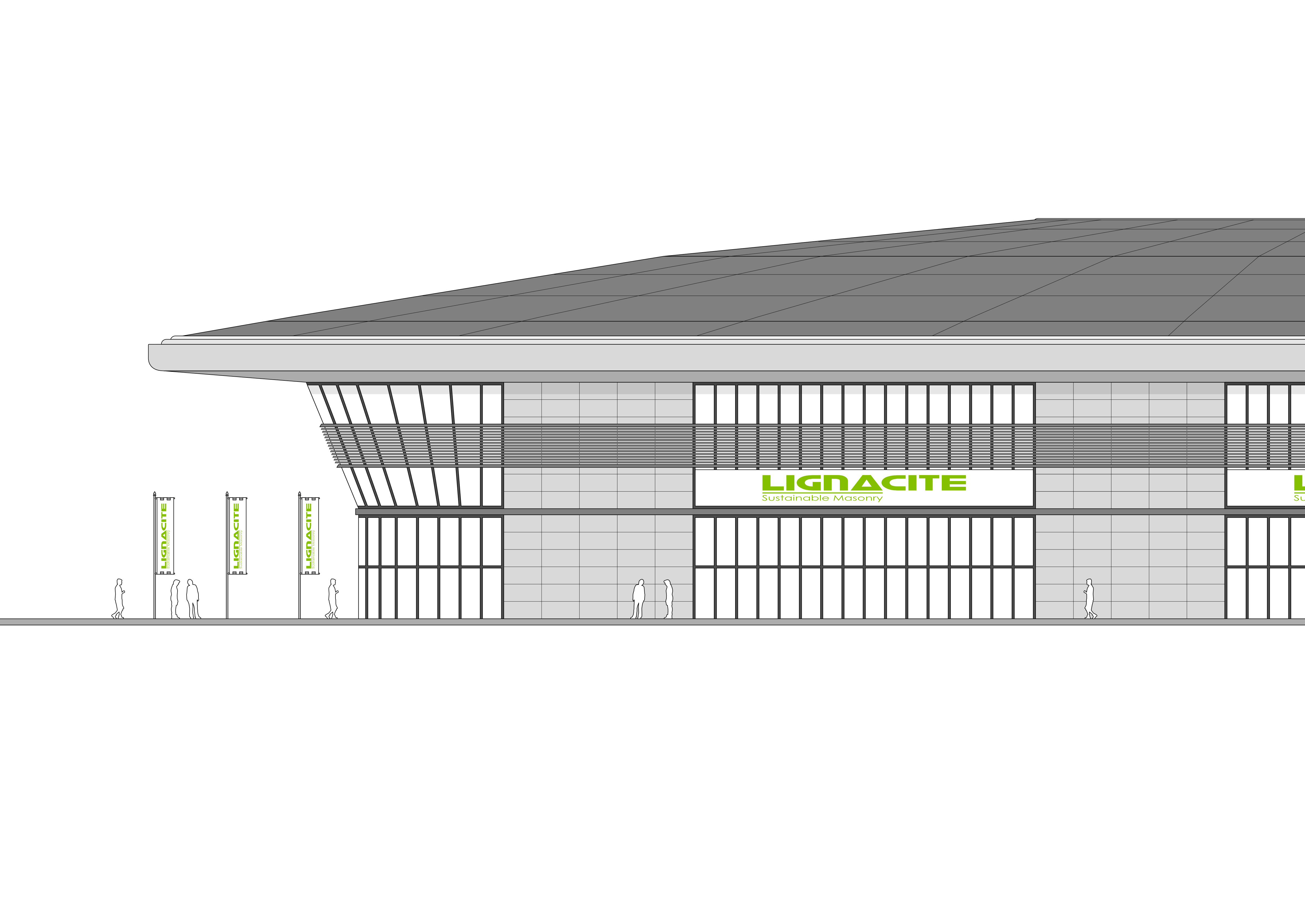

Leisure Centre

- 1 External Walls (Brick)

- 2 External Walls (Render)

- 3 Partition Walls & Inner Leaves (Painted)

- 4 Partition Walls & Inner Leaves (Fair Face)

- 5 Partition Walls & Inner Leaves (Plastered)

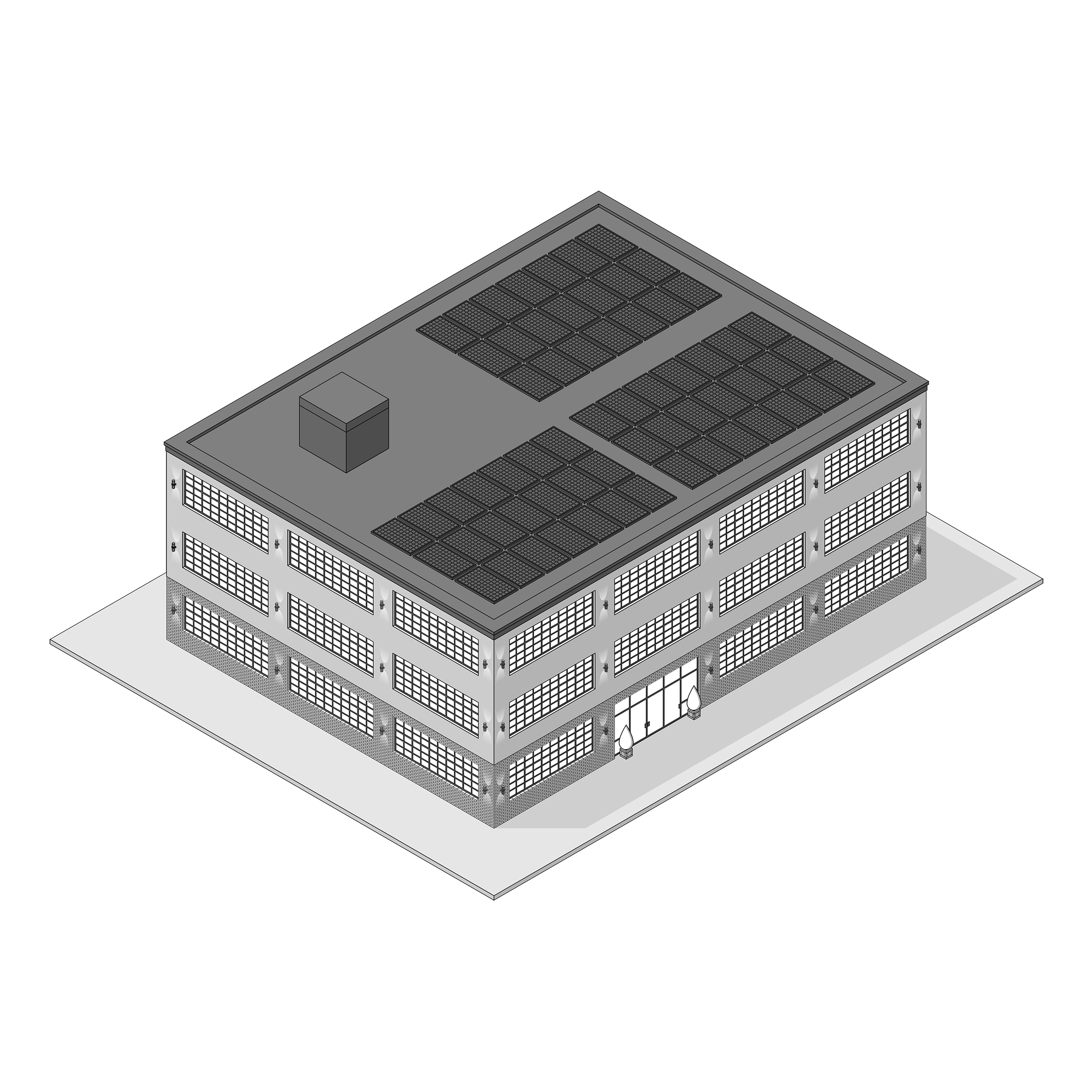

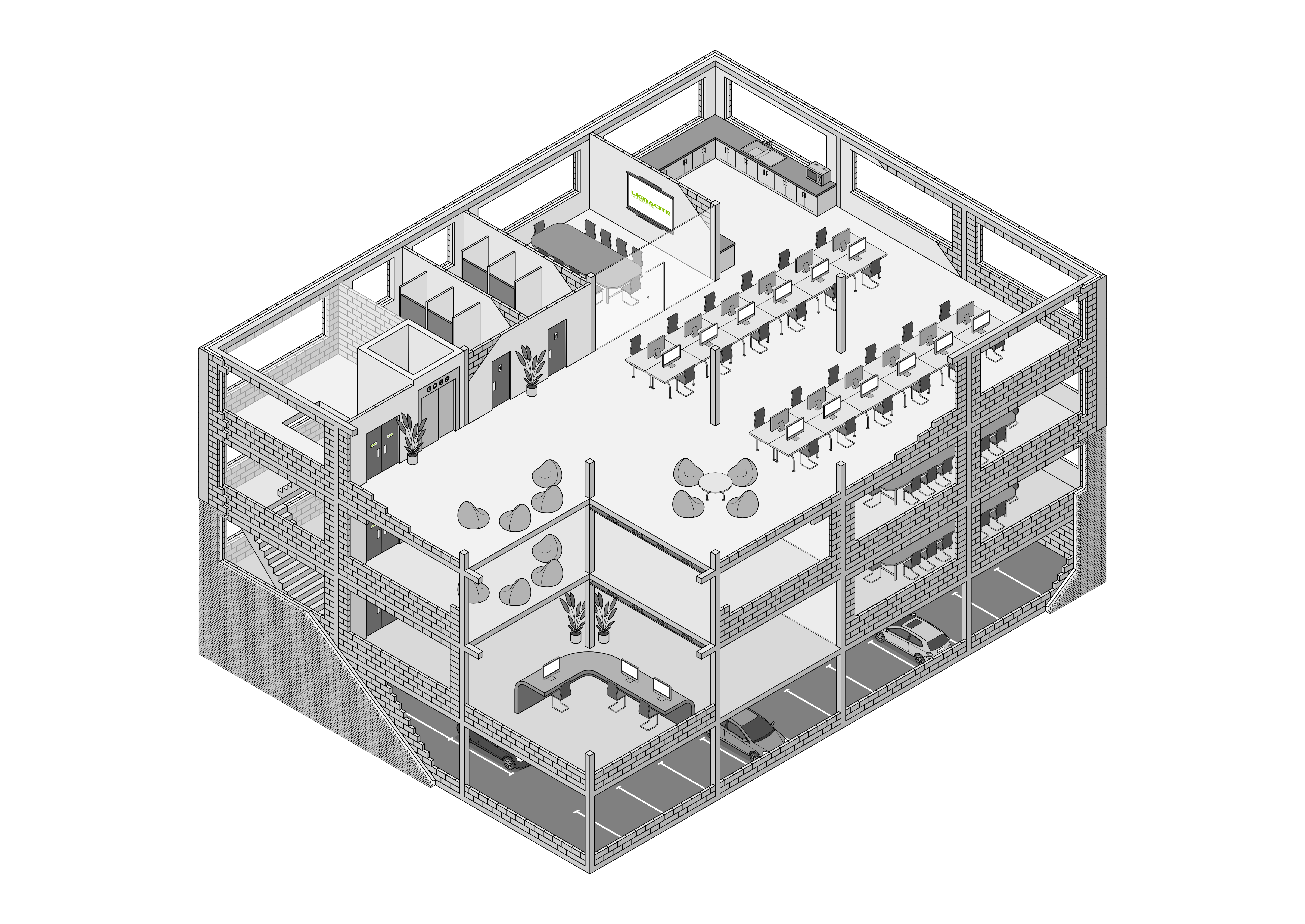

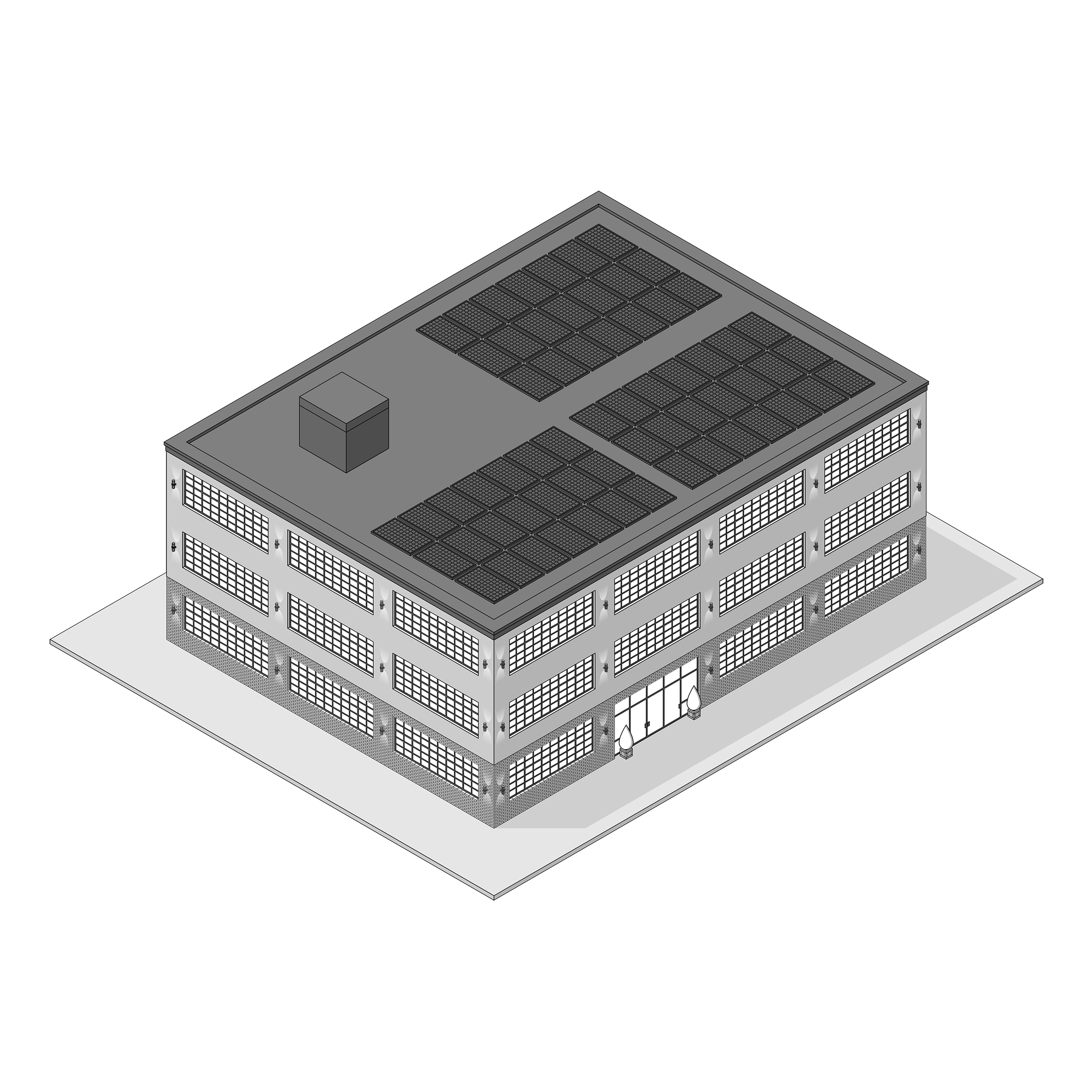

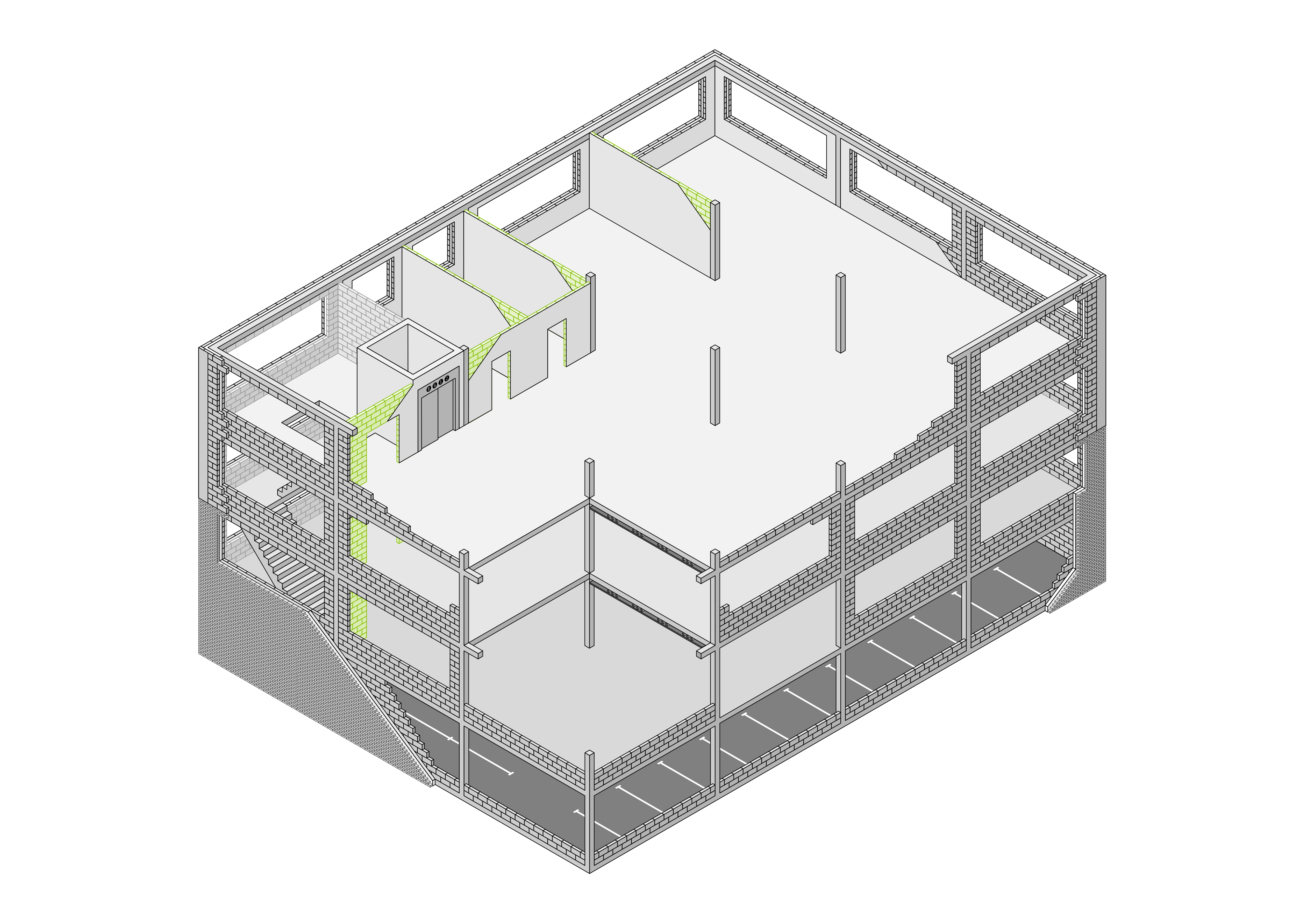

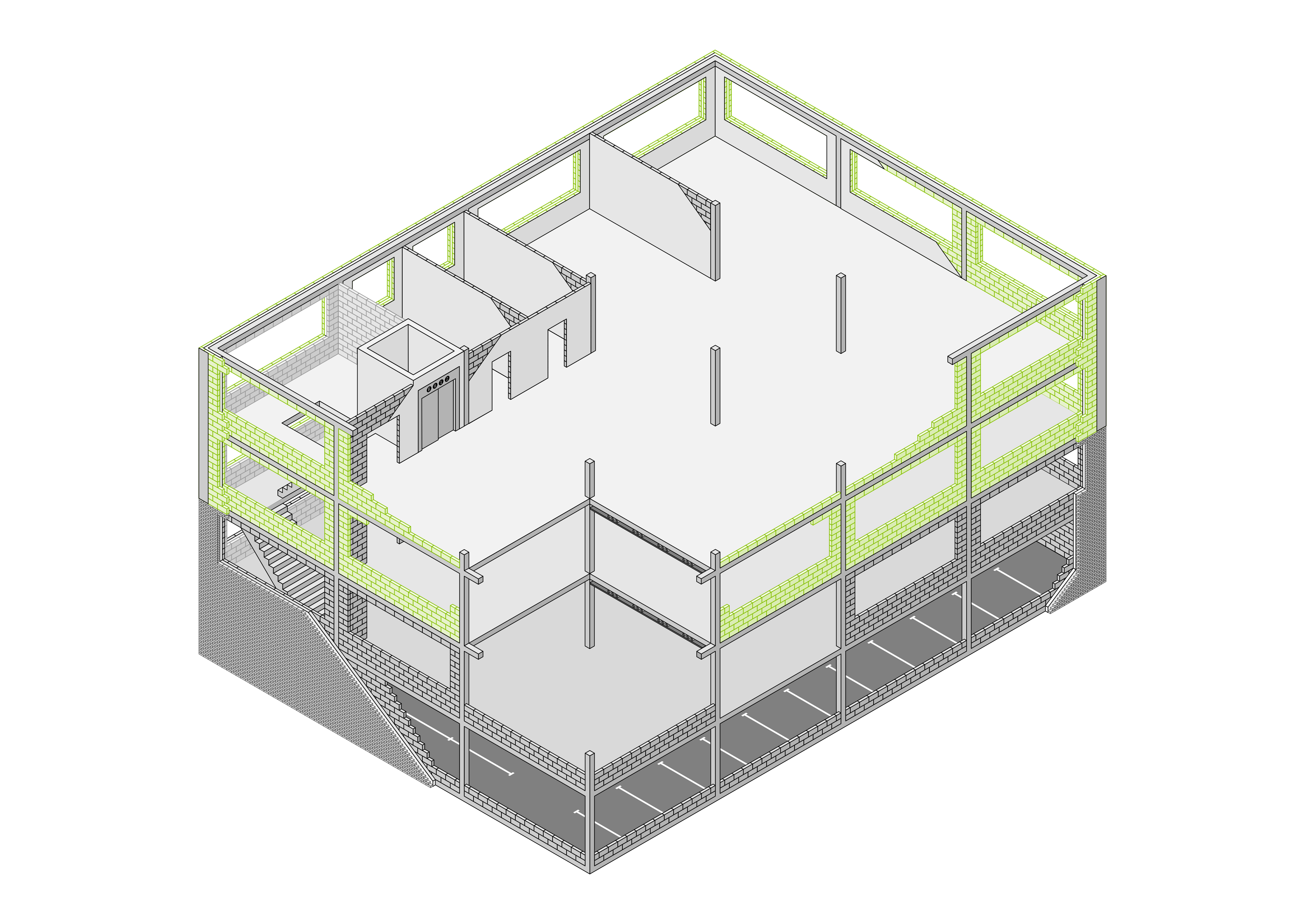

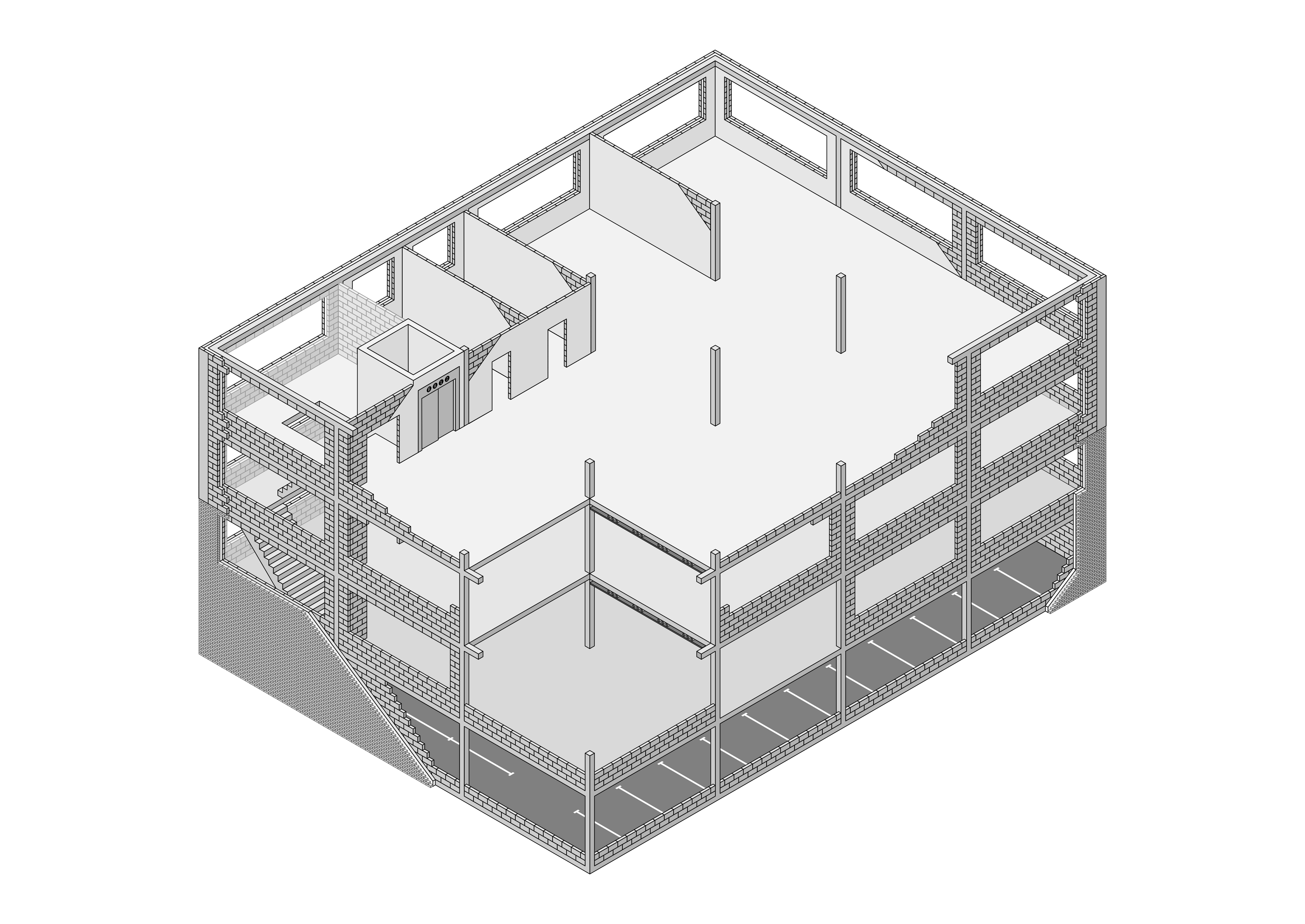

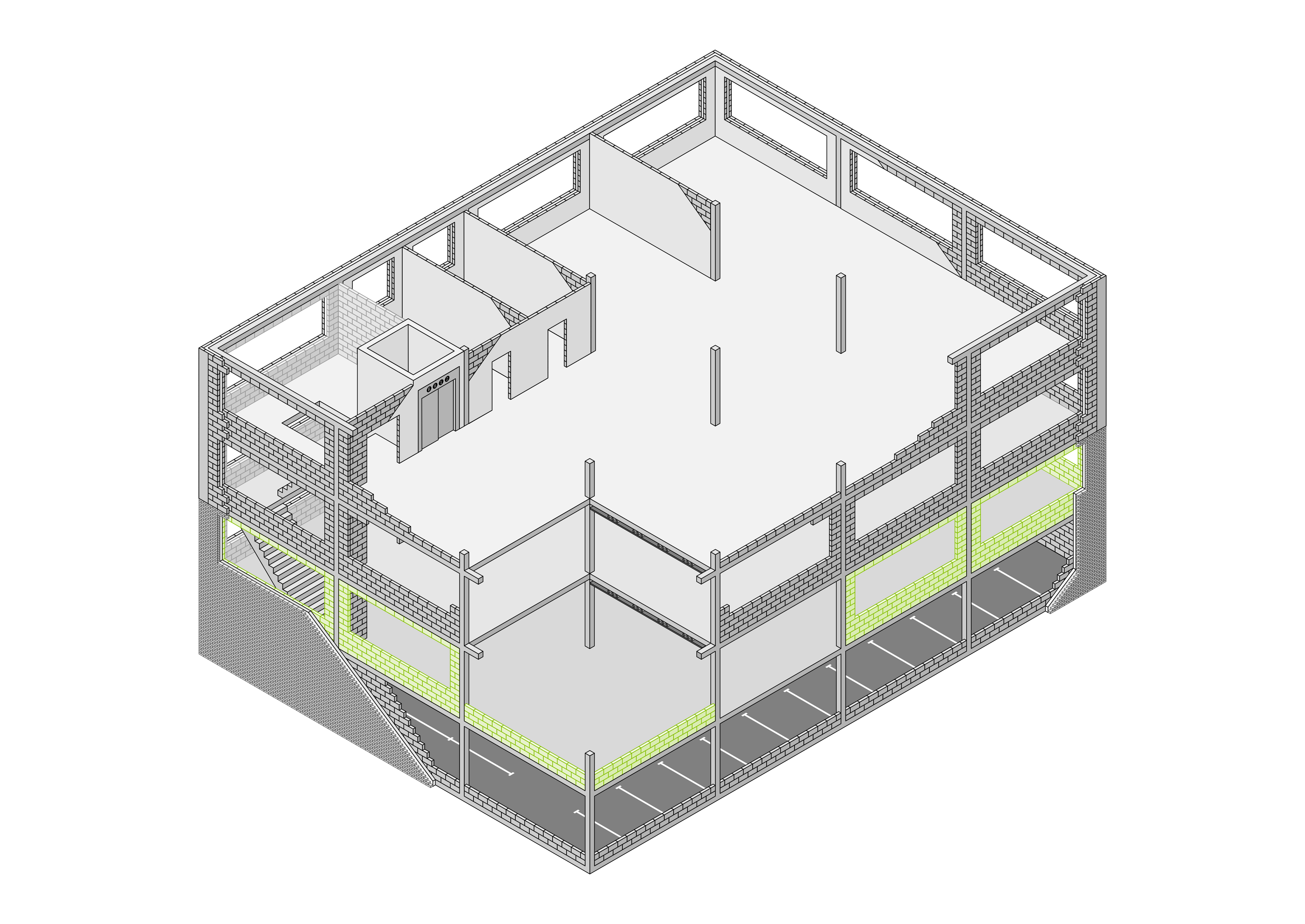

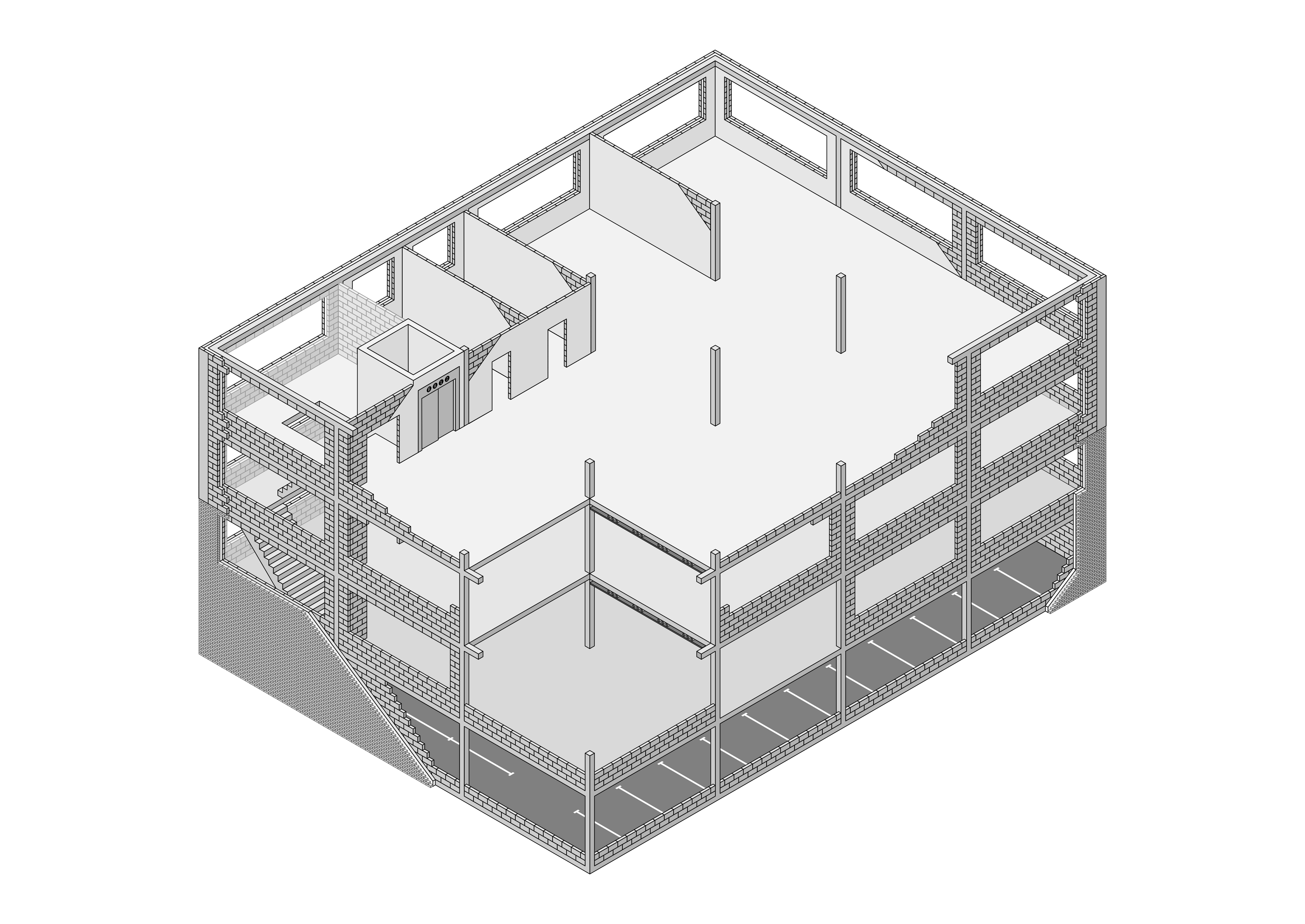

Other usesCommercial Building

Commercial Building

Information

Recommended Blocks: 3

Other usesCommercial Building

Commercial Building

Information

Recommended Blocks: 3

Other usesCommercial Building

Commercial Building

Information

Recommended Blocks: 3

Other usesCommercial Building

Commercial Building

Information

Recommended Blocks: 3

Other usesCommercial Building

Commercial Building

Information

Recommended Blocks: 1

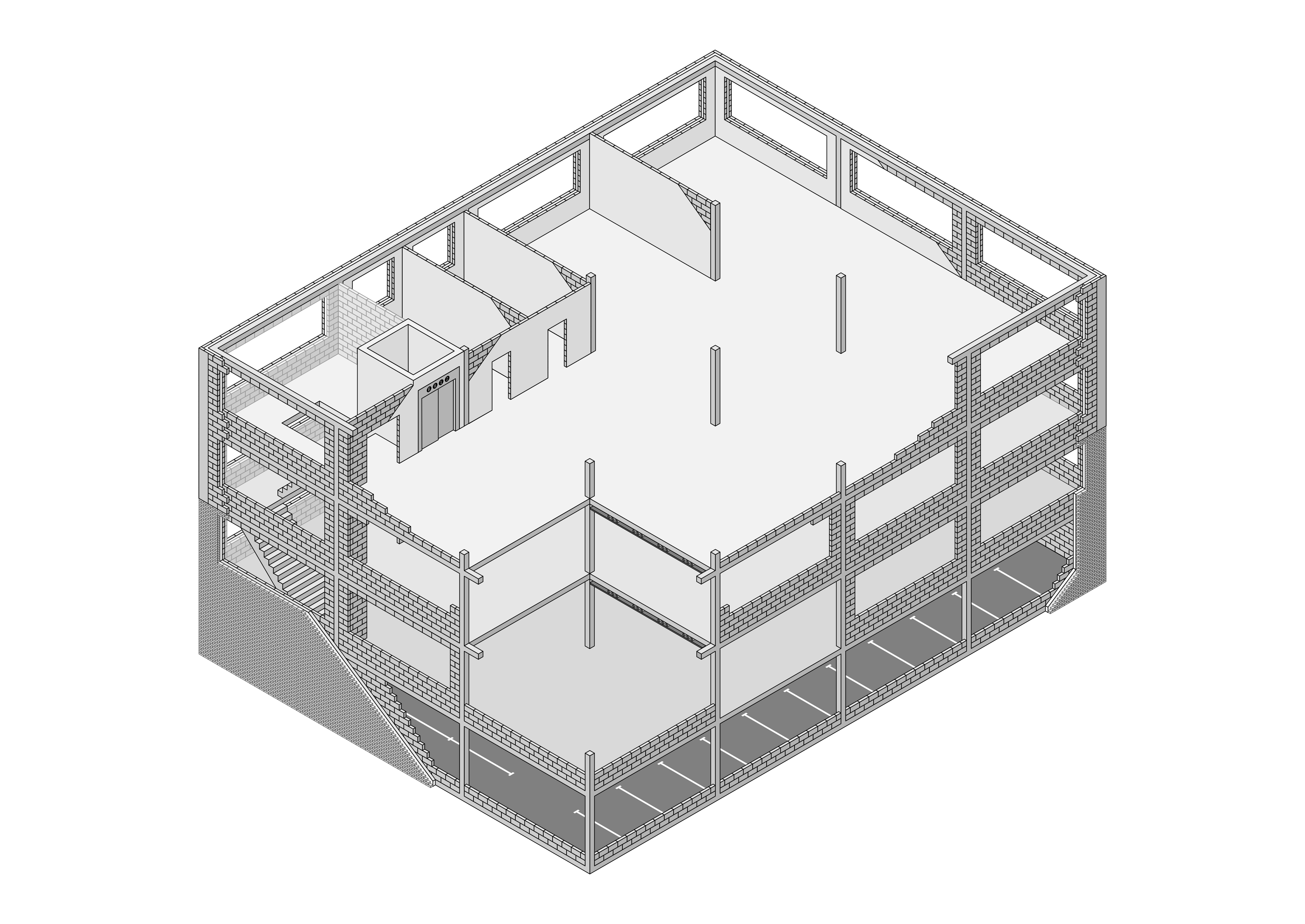

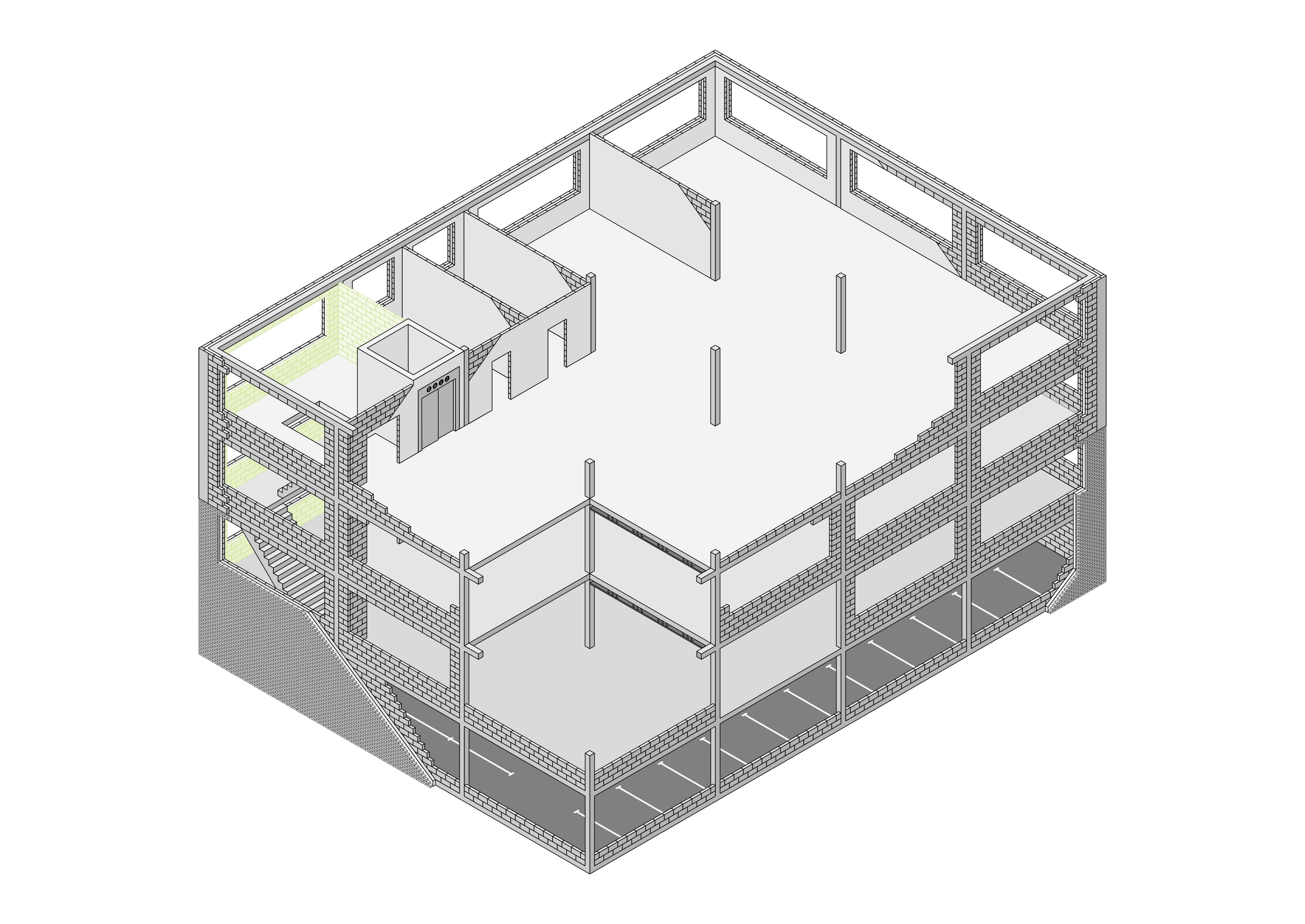

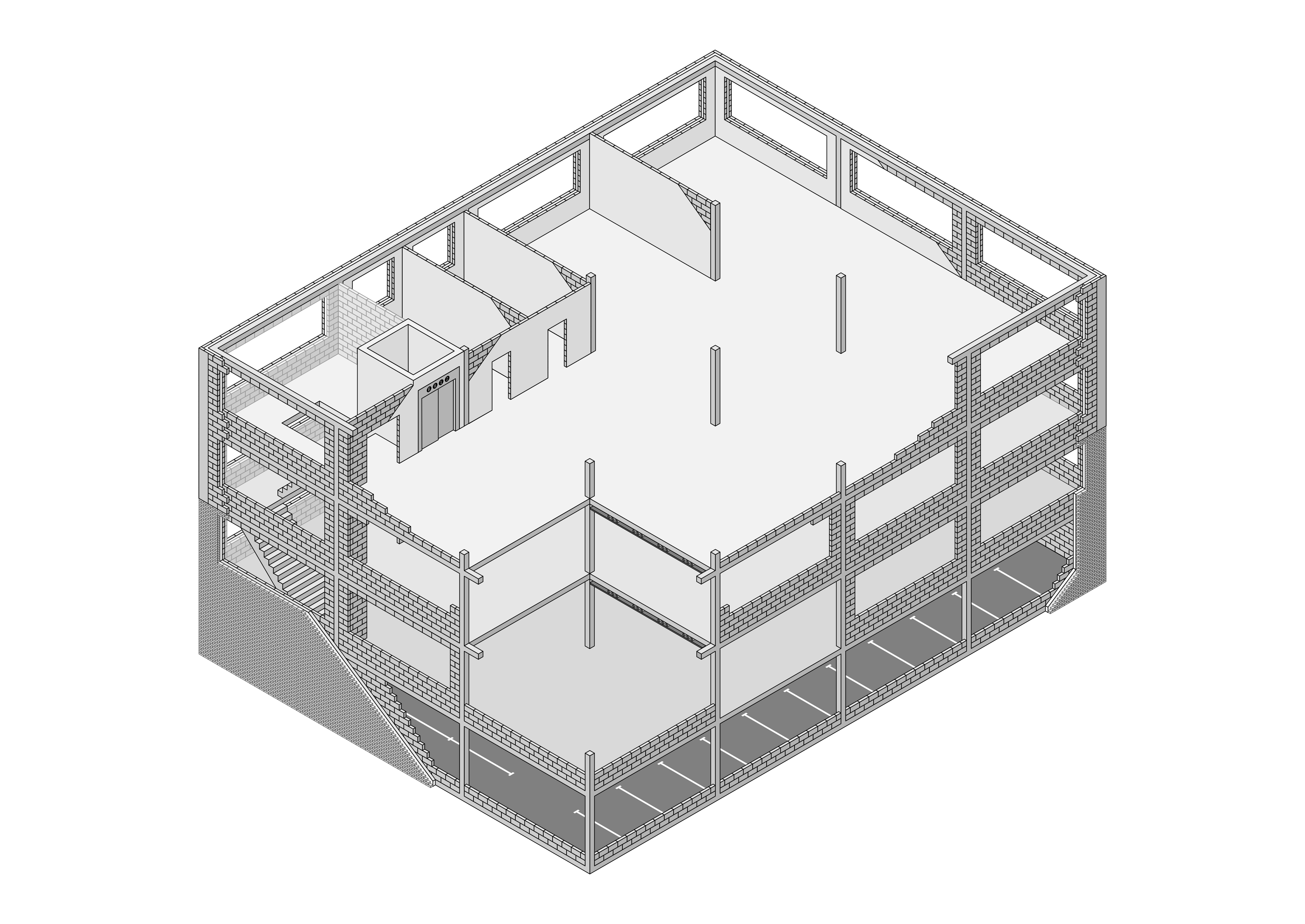

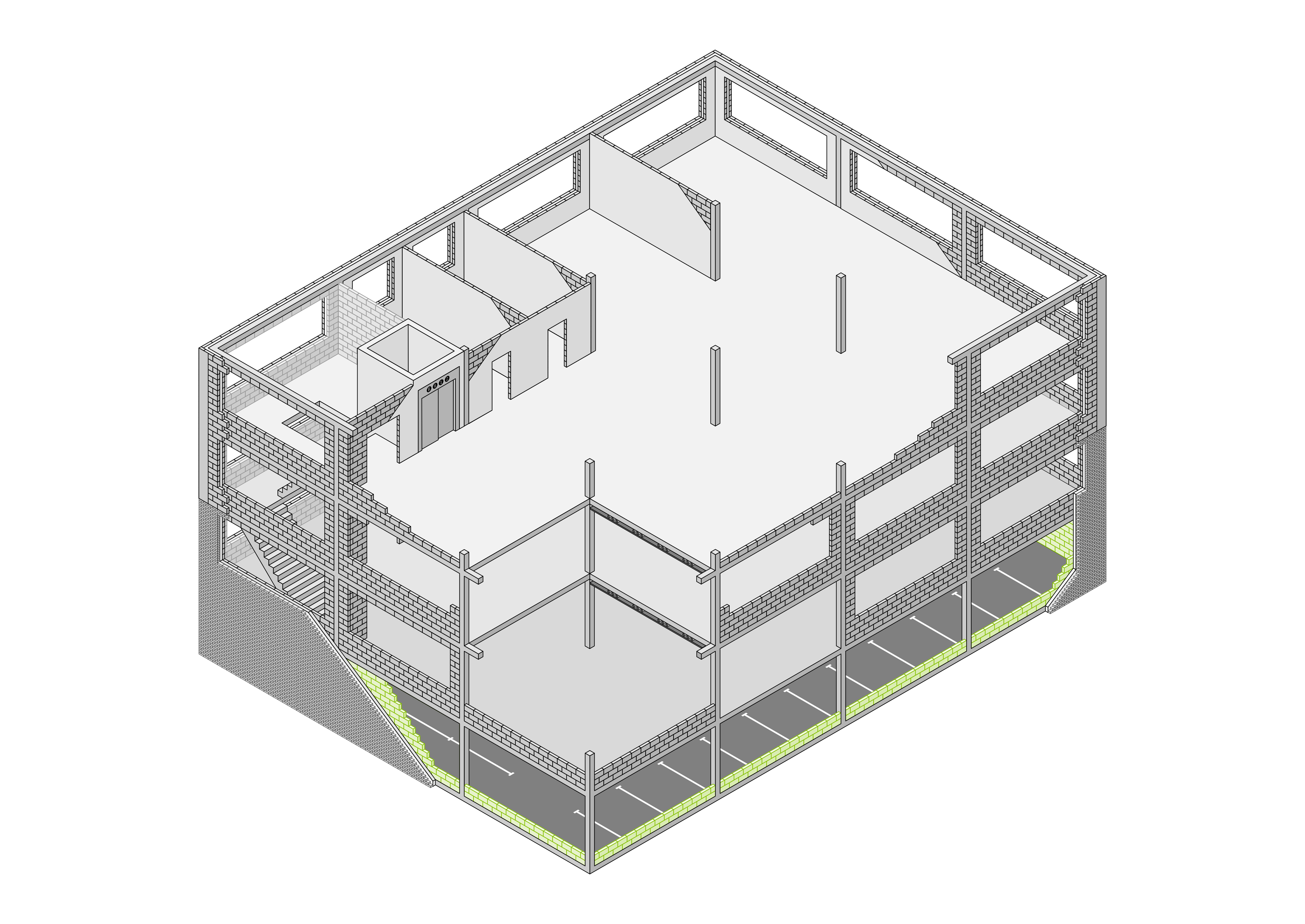

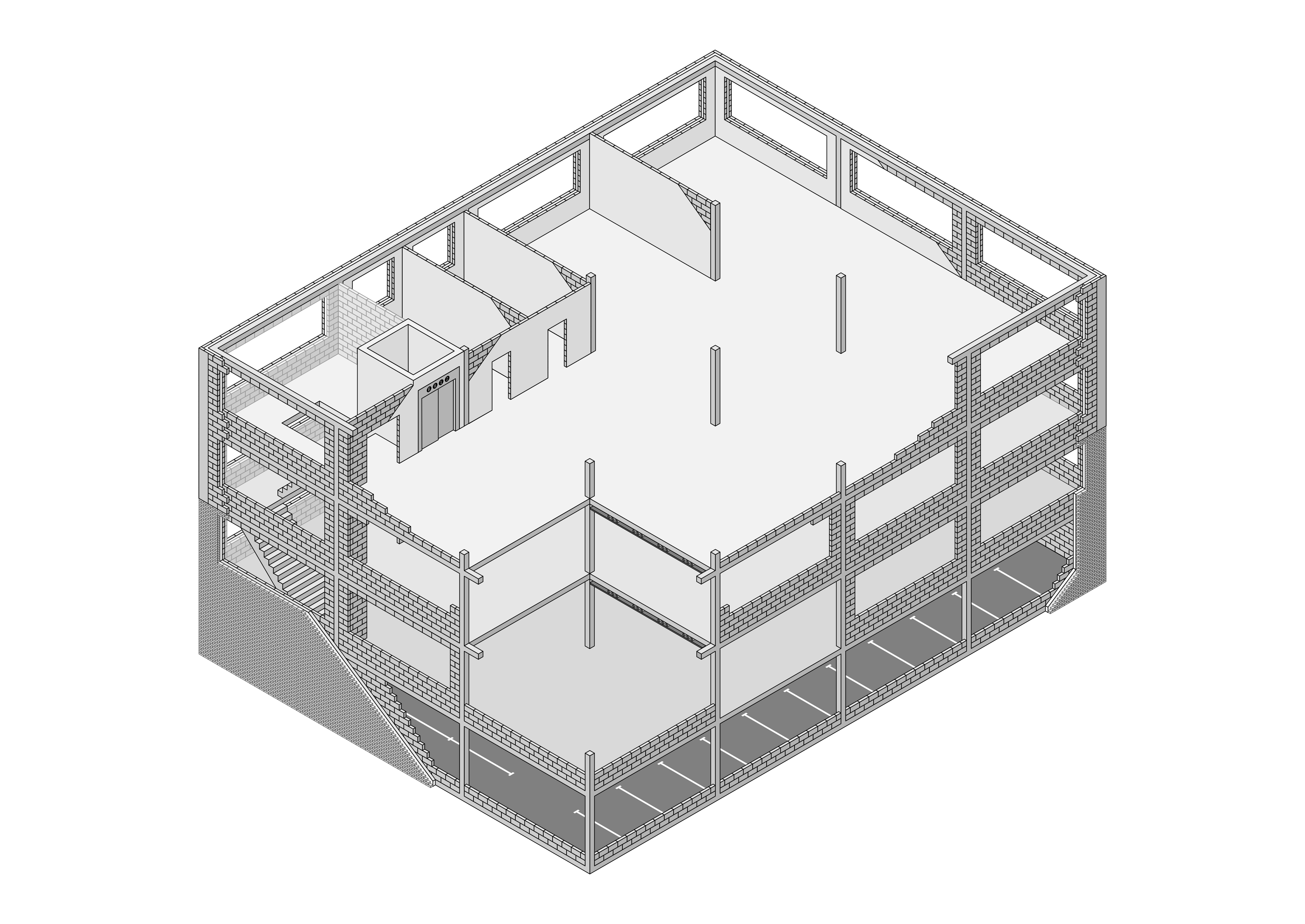

Other buildings

Commercial Building

- 1 Carpark (Blocks in Basements)

- 2 External Walls (Brick Cavity Block)

- 3 External Walls (Render Block Cavity)

- 4 Stair Core (Painted Blockwork)

- 5 Internal Walls

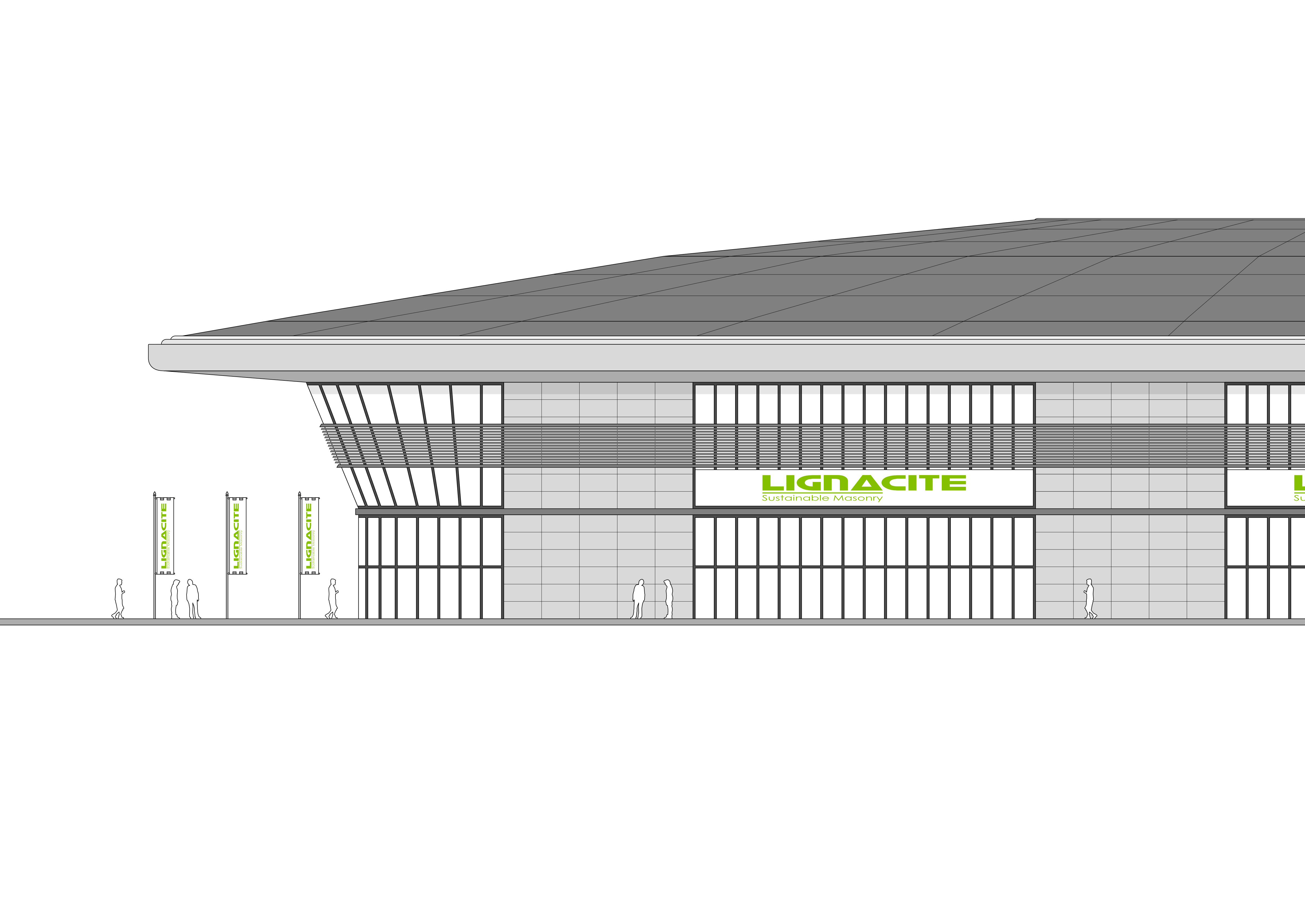

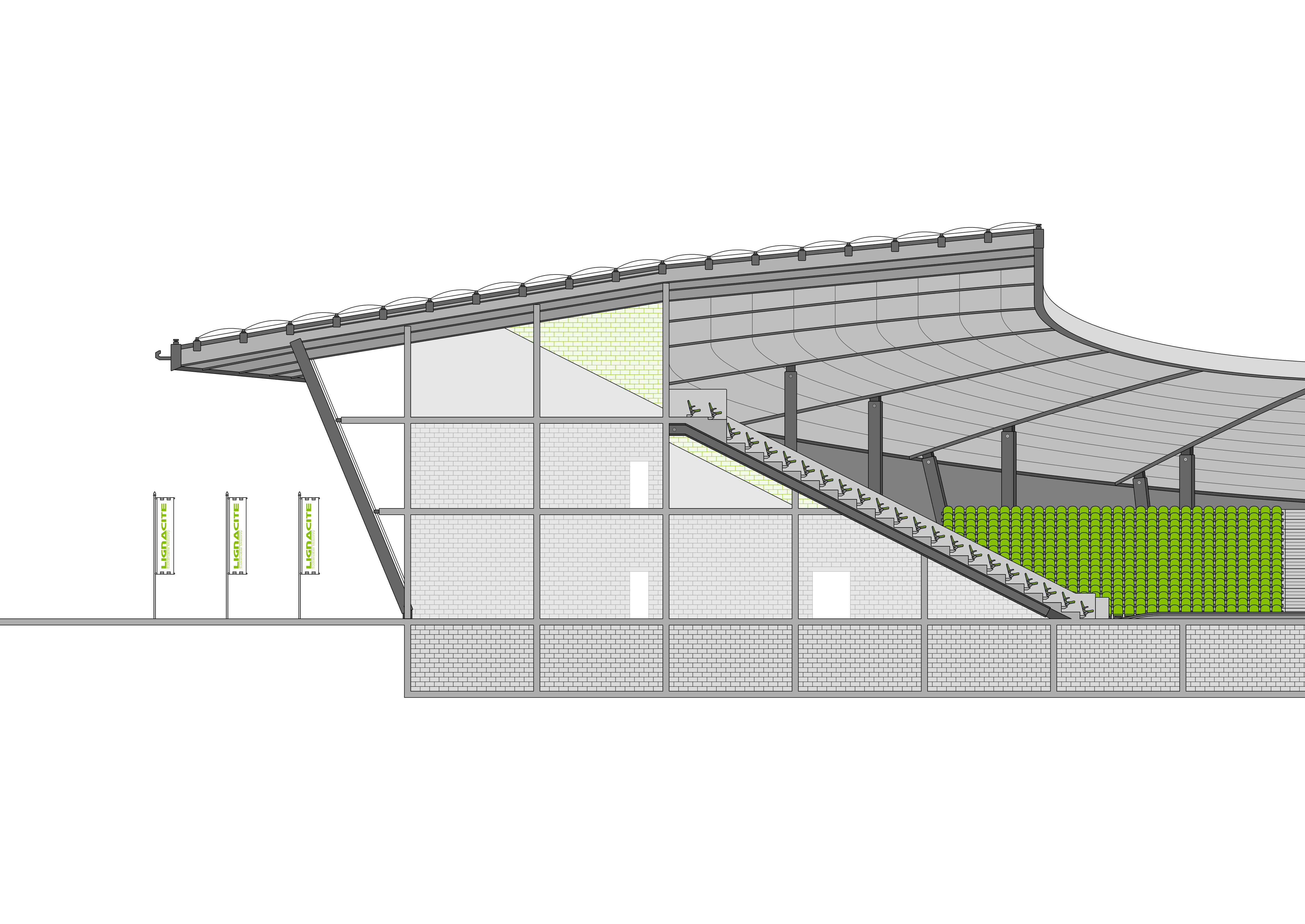

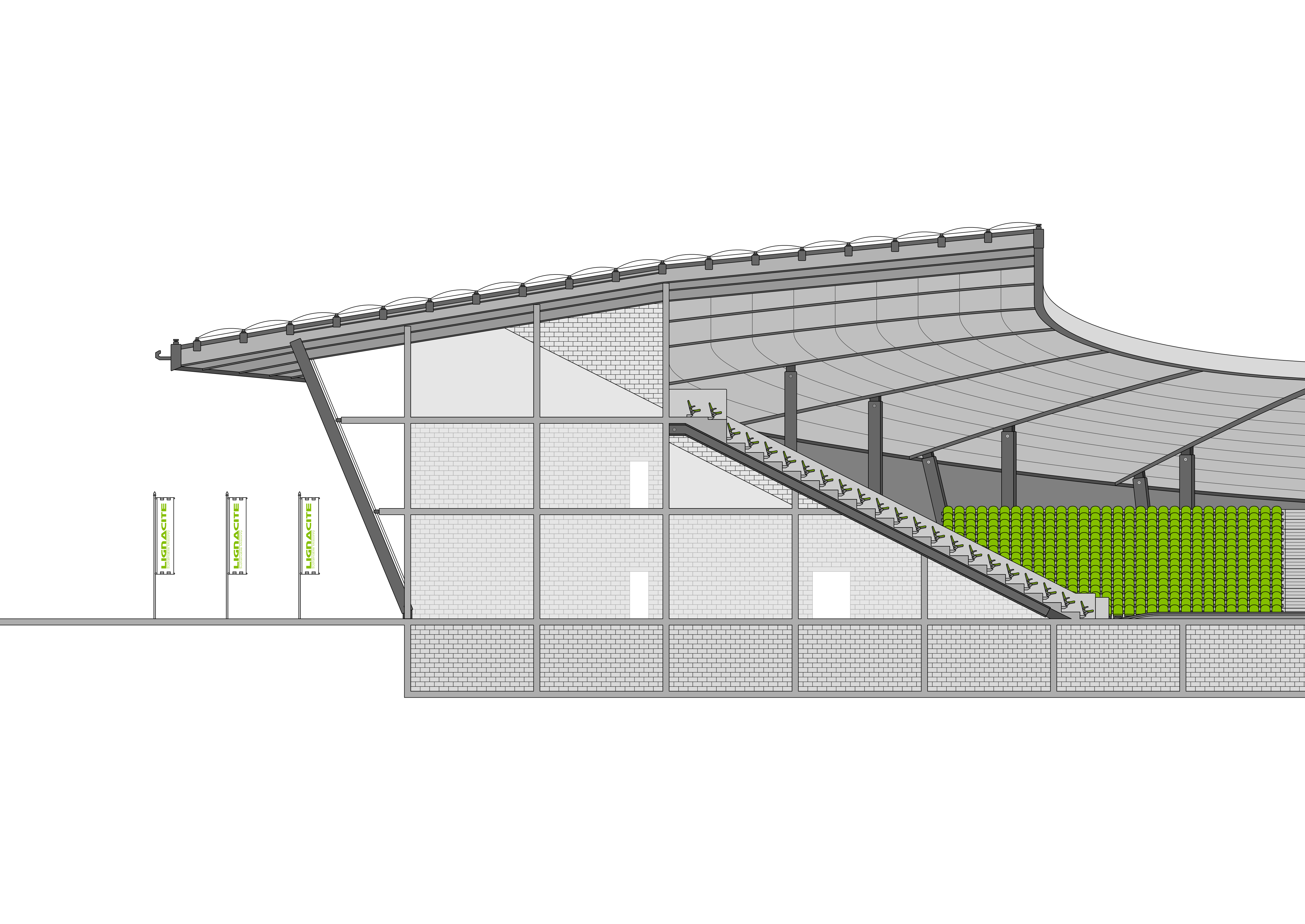

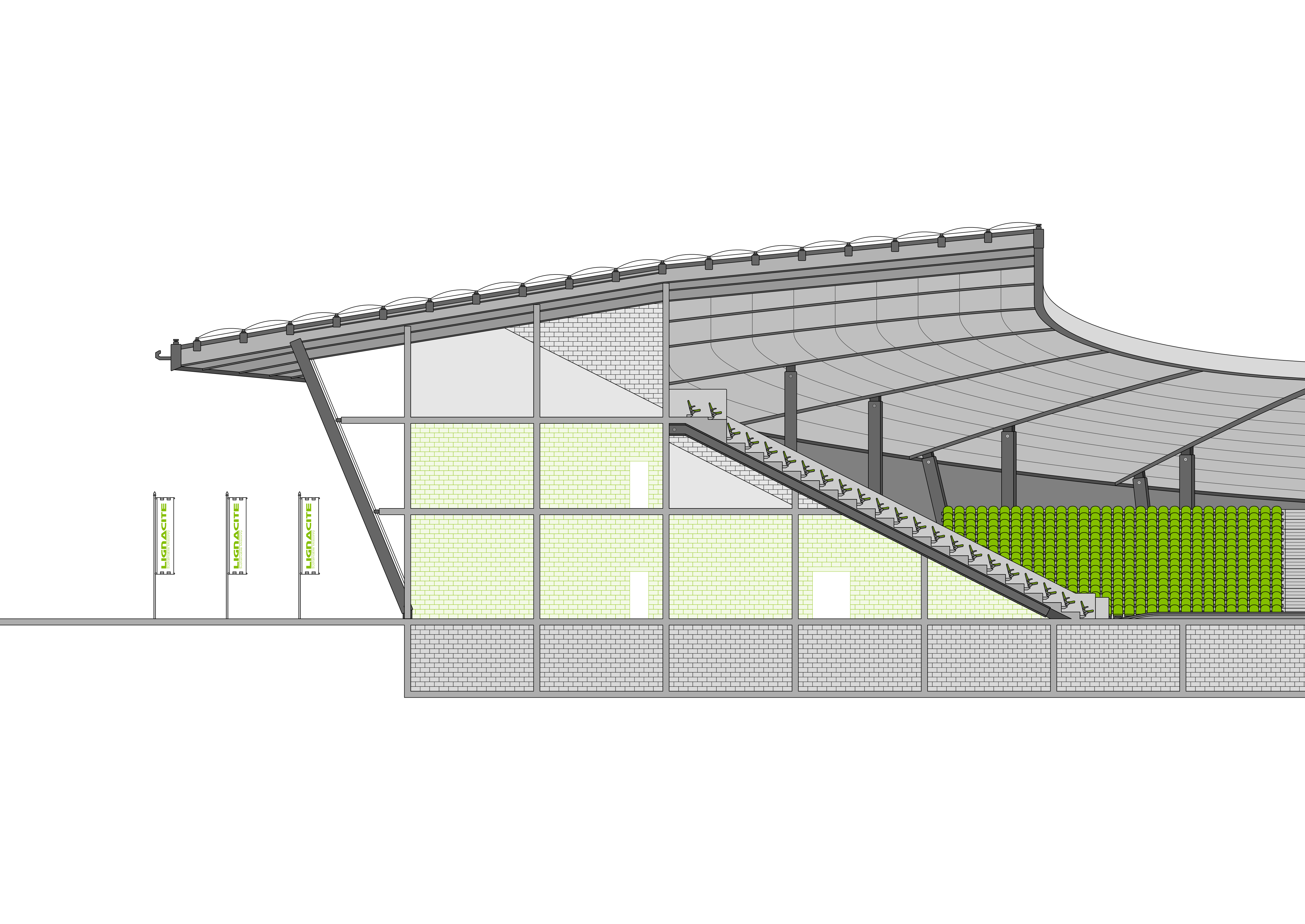

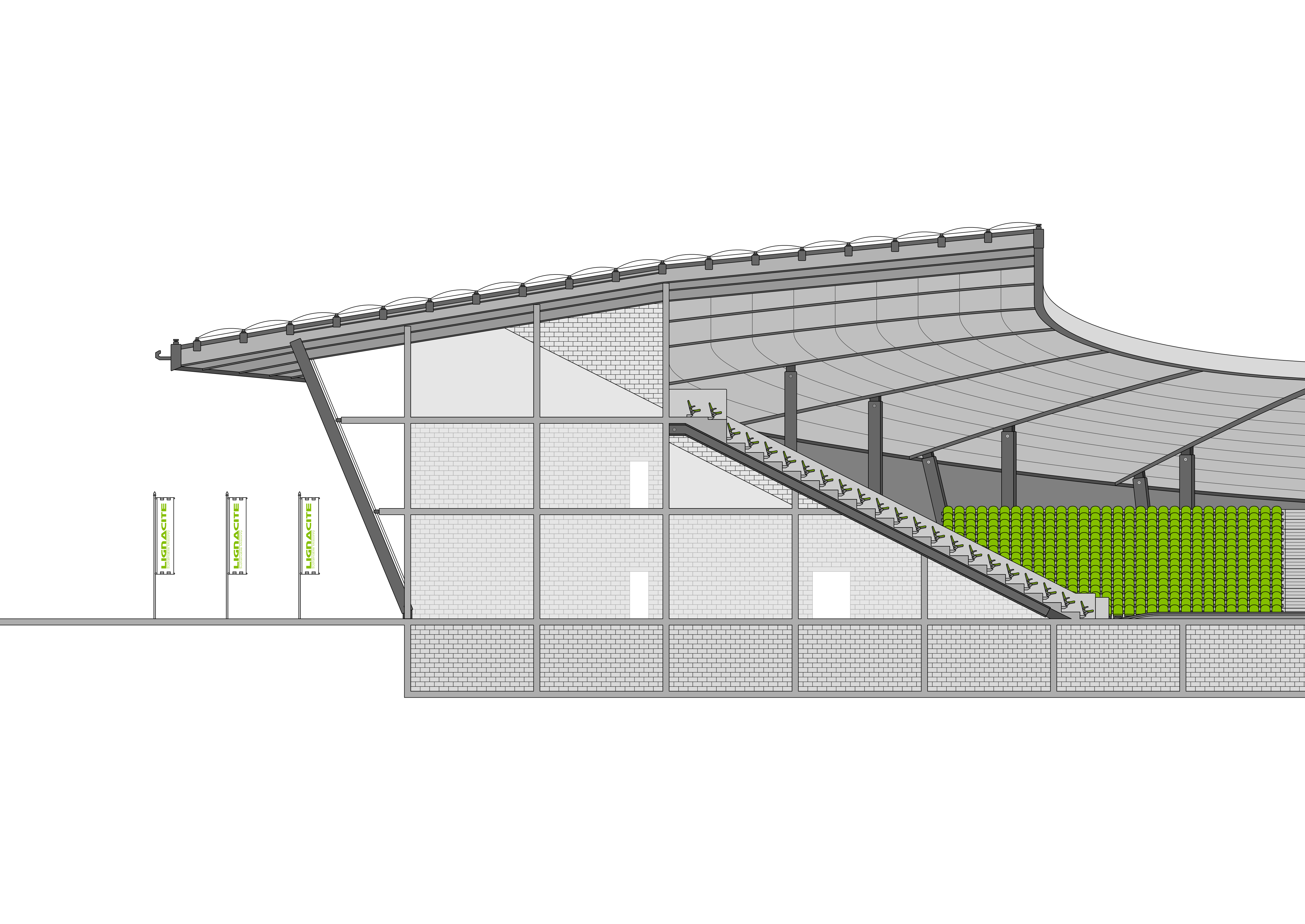

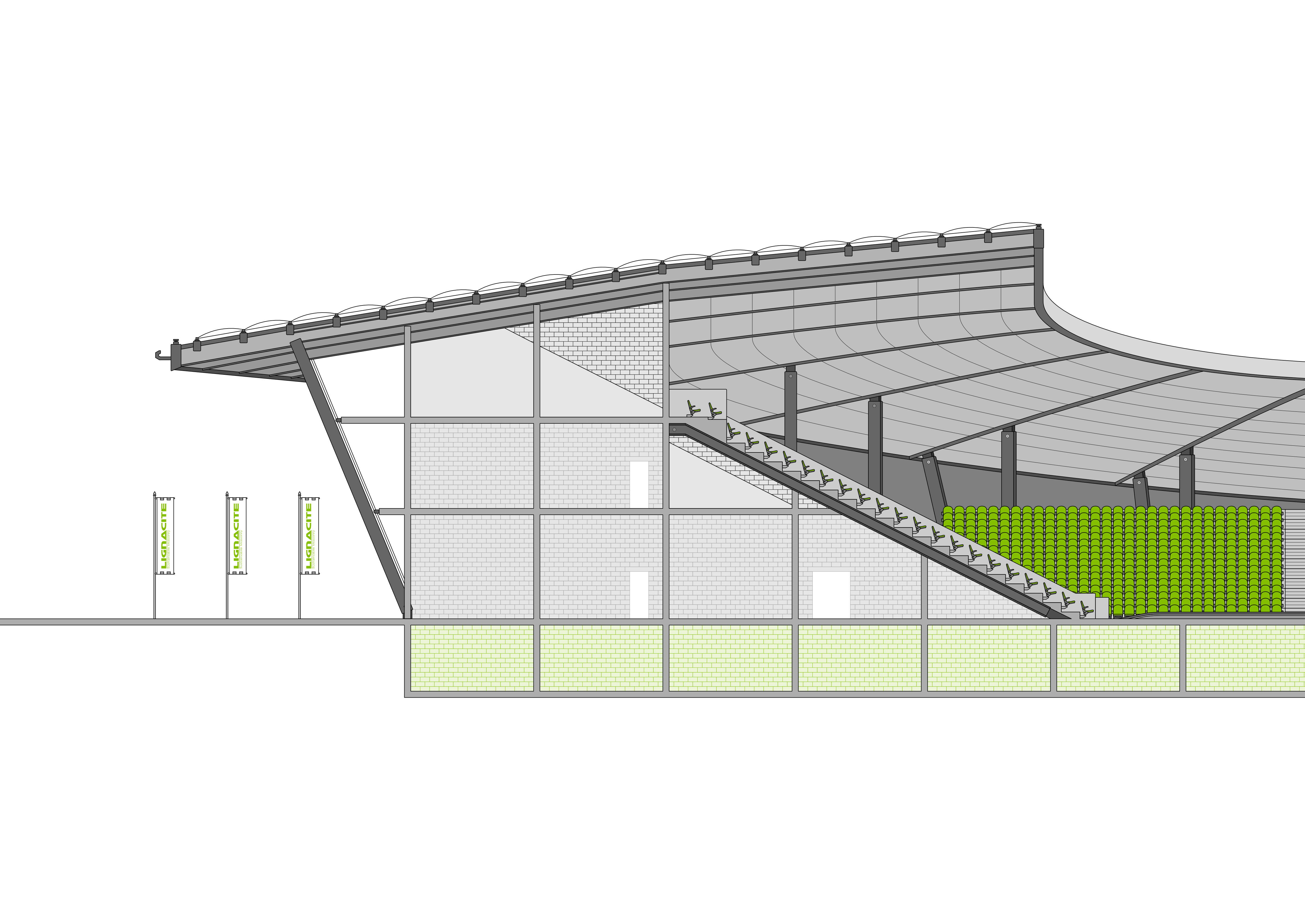

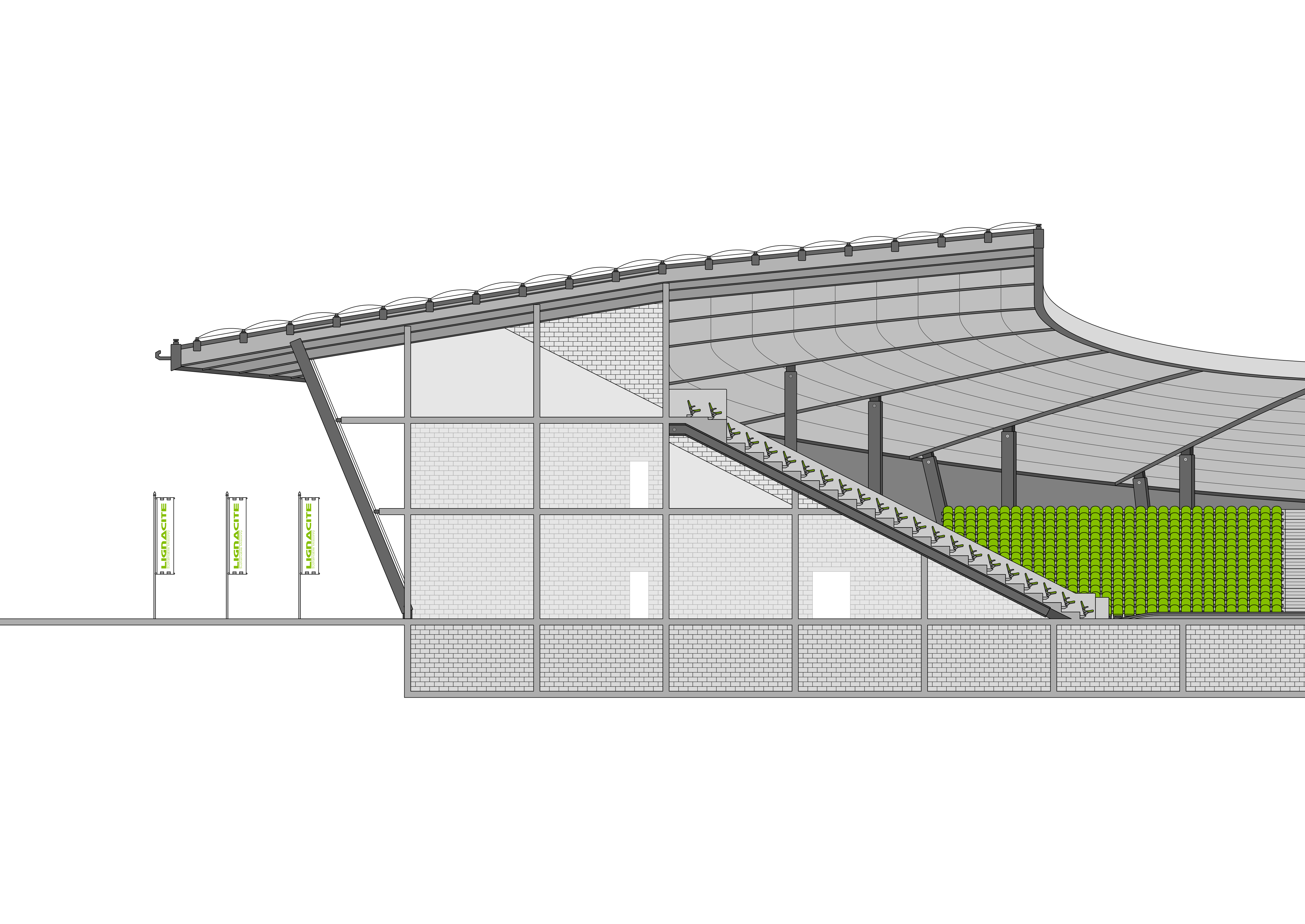

Other usesStadium

Stadium

Information

Recommended Blocks: 3

Other usesStadium

Stadium

Information

Recommended Blocks: 3

Other usesStadium

Stadium

Information

Recommended Blocks: 1

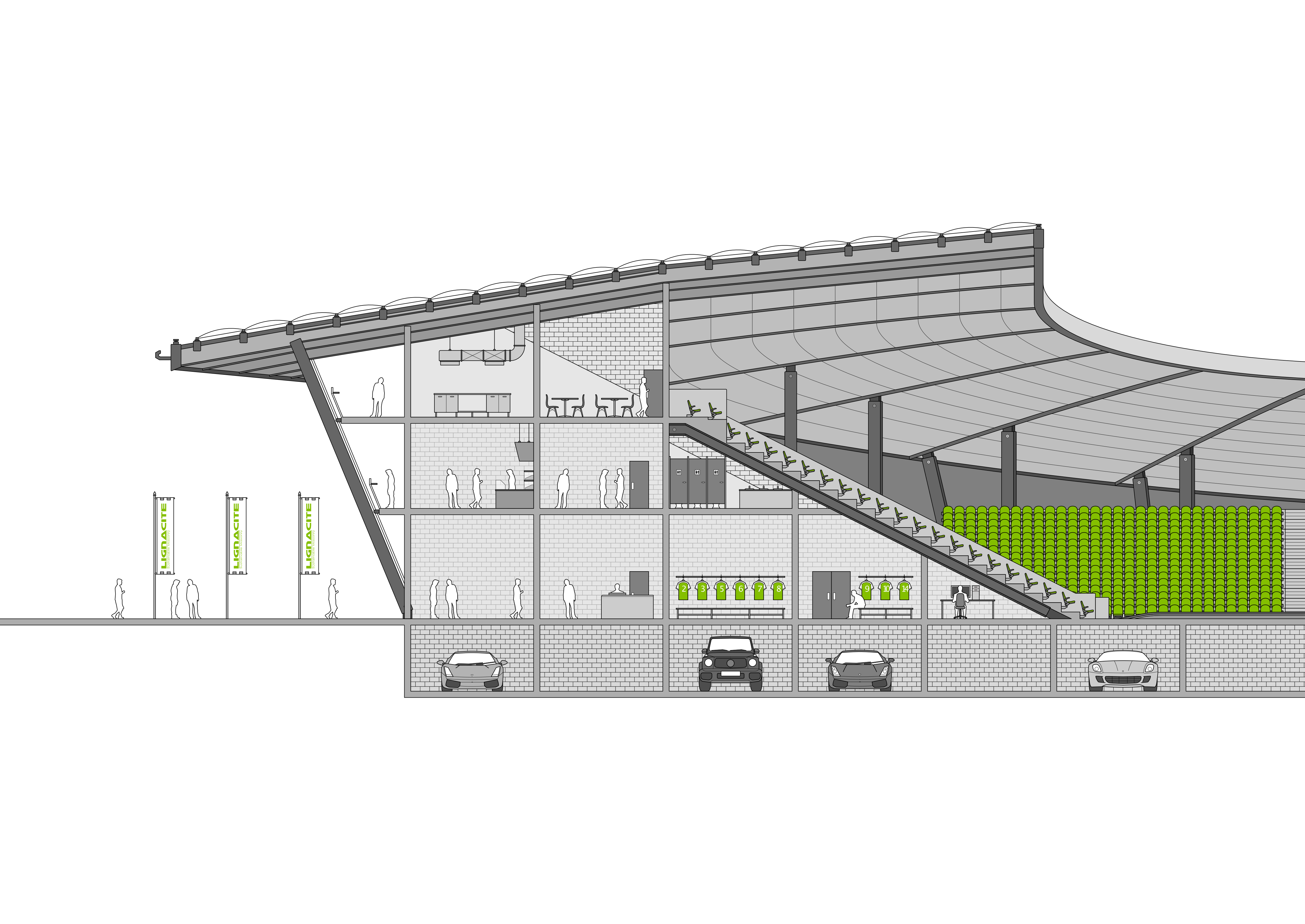

Other buildings

Stadium

- 1 Carpark (Blocks in Basements)

- 2 Internal Walls (Painted Blockwork)

- 3 Internal Walls (Plastered/Drylined Walls)

Domestic Housing

Leisure Centre

Commercial Building

Stadium

Specify Free with Lignacite

Built on a similar basis to NBS Source, our bespoke Specification Builder tool draws on key data for your selected product to produce a detailed Word or PDF document. And the added bonus? It’s completely free!

Specify with NBS Source

Have an account with NBS Source? Find and specify our products directly within their platform.

Our Mission:

To manufacture the best blocks for the construction industry, with outstanding service and innovation.

We pride ourselves on...

Sustainability

Sustainability is more than a ‘nice to have’. For us, it’s an absolute must. From locally sourced wood shavings and recycled material for our mixes to on-site energy management, our commitment is concrete.

Integrity

Clear communication, transparency, partnership and trust drive our work. We live by these standards every day and have done since our very beginning.

Follow Lignacite on Instagram

Curious about commercial construction? 🏢

Discover how Lignacite concrete blocks are transforming modern workplaces and retail spaces with durability, sustainability, and innovative design.

Explore the future of building with us.

#CommercialConstruction #Sustainability #InnovativeDesign

🚀 Big news on the certification front!

🌟 We`re proud to share that we`ve received the PAS 99 certificate!

This certification brings together our ISO 9001, ISO 14001, and ISO 45001 certifications under one umbrella, signifying our dedication to integrated management excellence.

Additional benefits include a much more streamlined assessment process with less repetition across the standards and much improved focus on integrated processes across the two sites.

From this point forward, we`ll be waving goodbye to separate certificates and embracing this unified standard as a testament to our commitment to quality, environmental responsibility, and occupational health and safety.

#Lignacite #PAS99 #CertificationAchievement

🐣🐰 Happy Easter Weekend from all of us at Lignacite!

As we embrace the arrival of spring, we`re excited for all the new projects blooming on the horizon. Count on us for all your block needs as we hop into the season together.

Have an egg-cellent Easter, filled with joy and laughter!

#Construction #BuildingMaterials #Lignacite

🌿 Curious about the artistry behind fair-faced blocks?

🏗️ Crafted with precision and care, these concrete blocks boast a flawless texture that`s unmatched in the world of building materials. But how do they achieve such perfection? Our latest blog spills the beans on their meticulous crafting process, from selecting the finest aggregates to ensuring uniform curing.

Visit the link in our bio to learn why fair-faced blocks are the epitome of concrete elegance!

#FairFacedBlocks #ConcreteDesign #Craftsmanship

🐰🌼 As Easter approaches, we want to ensure you`re aware of our adjusted opening hours to help you plan ahead:

Thursday 28th March: Open as usual

Good Friday: Closed

Easter Monday: Closed

Tuesday 2nd April: Open as usual

We appreciate your understanding and wish you a joyful Easter filled with peace and happiness!

🌿 Curious about the intersection of sustainability and construction amidst climate change?

Our latest blog post has the answers! Explore how developers, architects, and builders are adapting their practices to promote sustainability, with methods like BREEAM leading the way.

Tap the link in our bio to delve deeper!

#BREEAM #Sustainability #Construction

🧱 Spring has sprung, and brighter days are ahead for construction projects!

Our Brandon and Nazeing sites are fully stocked with a diverse range of blocks, ensuring you have access to the materials you need to thrive this season.

Explore our stock today and gear up for the upturn!

#Construction #BuildingMaterials #Lignacite

Discover the building blocks behind one of London`s most iconic sporting landmarks: the Emirates Stadium! ⚽

From the roar of football fans to the thrill of sports, this structure has captured the imagination of millions. We`re honoured to have contributed to its construction with our Lignacite Paint Grade and Lignacrete blocks.

Explore more iconic projects on our website.

#EmiratesStadium #AresenalFootballClub #SirRobertMcAlpine #Lignacite

Celebrating the success of our updated Brandon factory, which has been in operation since last year!

From the beginning, sustainability has been our mission. With features like power factor correction and solar panels, we’re setting new standards for eco-friendly masonry. 💡🌱

#Sustainability #Innovation #Factory

🚛 Exciting news! Meet the newest additions to our fleet: Scania S500`s!

🎉 These sleek vehicles are joining our lineup to help us deliver more loads each day. With increased production from our new plant, we`re ready to serve you better than ever before!

#FleetExpansion #ScaniaS500 #DeliveryService